Differences between hot runner mold and cold runner mold

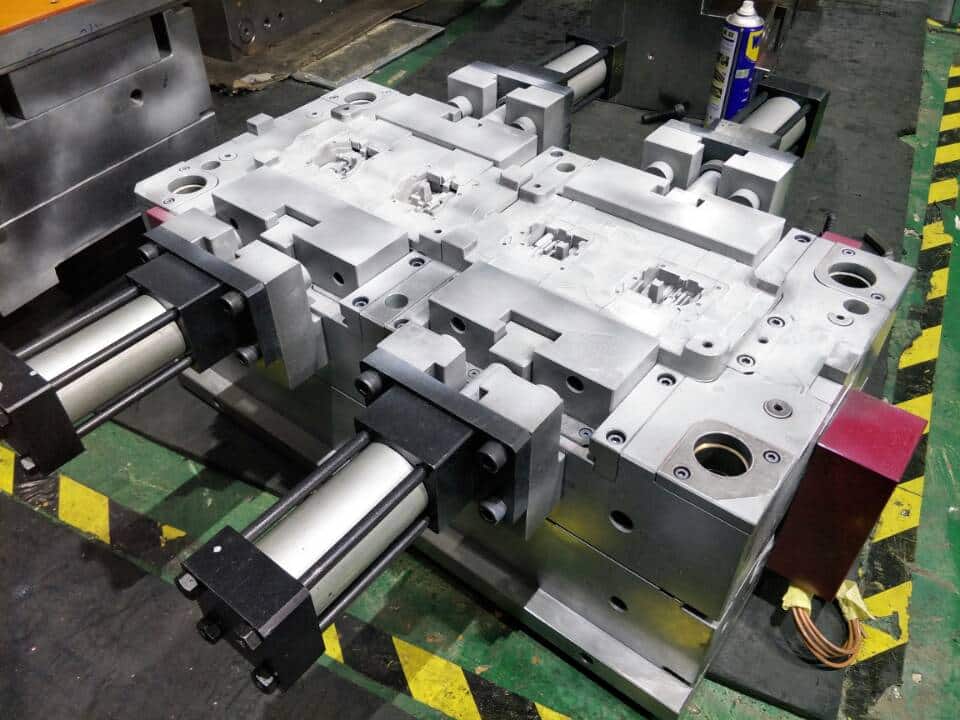

plastic injection mold

The mold is a kind of molding equipment, with good molding effect and basically no deformation after molding. Now there are more and more types of molds. The main reason why the hot runner mold is widely used is its hot runner system. What is the difference between it and cold runner mold?

In fact, the difference between the two is mainly in hot runner and cold runner:

1、 Cold runner: refers to the part between the mold inlet and the product gate. The plastic in the runner is kept flowing by the injection pressure and its own heat. The runner is a part of the molding material, but it is not a product. So when we design the mold, we should not only consider the filling effect, but also consider how to save materials by shortening and narrowing the runner.

2、 Hot runner: As a common part of the hot runner mold system, it is used to ensure that the plastic in the runner and gate remains molten by heating. Since a heating rod or heating ring is set near or in the center of the runner, the entire runner from the injection molding machine nozzle outlet to the gate is in a high temperature state, so that the plastic in the runner remains molten. After the hot runner mold is stopped, it is generally not necessary to open the runner to take out the condensate. When the hot runner mold is restarted, it is only necessary to heat the runner to the required temperature. The hot runner is the extension of the injection molding machine nozzle.

Hot runner mold and cold runner mold have different runner systems, so the types of products to be molded are different. Before selecting a mold, you must be clear about the differences between different types of molds

Now let’s talk about their advantages and disadvantages;

1、 Cold runner;

1. The cost of cold runner is low, just one sprue sleeve, dozens to hundreds of them.

2. Simple processing and low precision requirements.

3. Produce more waste, runner and material handle.

4. The molding cycle is long, and the mold with high requirements for product quality is unstable.

2、 Hot runner;

1. The cost of hot runner is high, 3000-5000 yuan for an open hot nozzle, and more than 10000 yuan for a needle valve hot nozzle.

2. It is difficult to process, with many procedures and high requirements for processing accuracy.

3. Save materials. Generally, the life of each set of mold installed with hot runner is more than hundreds of thousands of molds, so the material saved will be much more.

4. The molding cycle is shortened, and the product quality is improved. The current hot runner can accurately control the temperature of each section of the hot runner, so that the materials can be evenly injected into the mold cavity. The mold temperature and machine control can greatly improve the product quality.

5. The installation of hot runner system is more conducive to automatic production in the workshop.