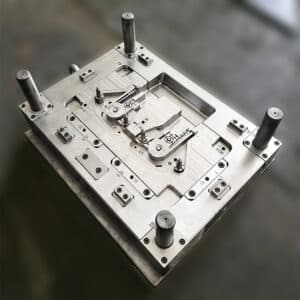

Causes And Solutions Of Shock Lines, Swelling And Bulging In Injection Molded Products

Causes and solutions of shock lines, swelling and bulging in injection molded products The surface of rigid plastic parts such as PS, etc. near the gate forms dense corrugations centered on the gate, sometimes called shock lines. The reason for this is that when the melt viscosity is too large and the mold is filled in the form of stagnant flow, the front-end material quickly condenses and shrinks when it touches the surface of the