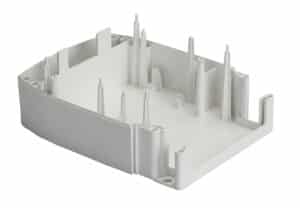

A batch of injection mold moving pictures to let you understand all the plastic process!

Plastics, a polymer, have a wide variety of processing methods. Each method has its advantages and disadvantages and is better suited for a specific application. Let’s see how they are processed next with the relevant interesting motion pictures! Injection Molding Machines Injection Molding Injection molding is a manufacturing method in which parts are made by injecting material into a mold. The primary method of processing plastic is injection molding. In this process, the plastic is