Eight Common Injection Mold Structure Classification

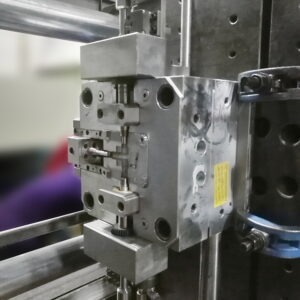

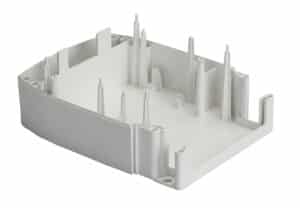

Eight common injection mold structure classification One. Single parting surface injection mold When the mold is opened, the movable mold and the fixed mold are separated, so as to take out the plastic parts, which is called single parting surface mold, also called double-plate mold. It is the simplest and most basic form of injection mold, which can be designed as single-cavity injection mold or multi-cavity injection mold according to the need, and is the