The difference between injection moulds and plastic moulds

Many people can’t tell the difference between injection molds and plastic molds, and many people even think that they are the same kind of molds, just called different. Although injection molds and plastic molds are both molds, but there is a difference between them. Want to figure out the difference between the two, first and Xiaobian together to understand what is injection mold, what is plastic mold.

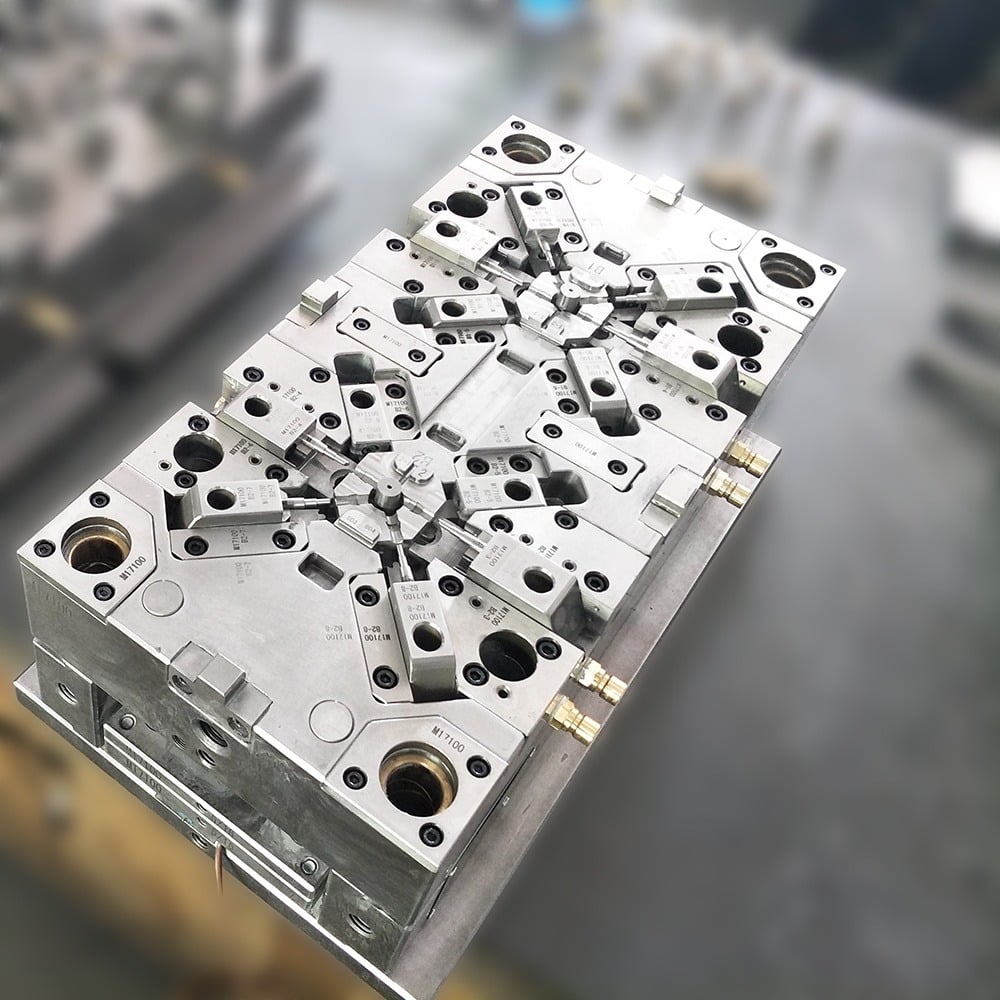

Plastic mold, a combination of plastic mold for compression molding, extrusion, injection, blow molding and low foam molding, mainly includes a concave mold with variable cavity composed of concave mold combination substrate, concave mold assembly and concave mold combination card plate, a convex mold with variable core composed of convex mold combination substrate, convex mold assembly, convex mold combination card plate, cavity cut-off assembly and side cut-off combination plate. Coordinated change of mold convex and concave dies and auxiliary molding system. A series of plastic parts of different shapes and sizes can be processed.

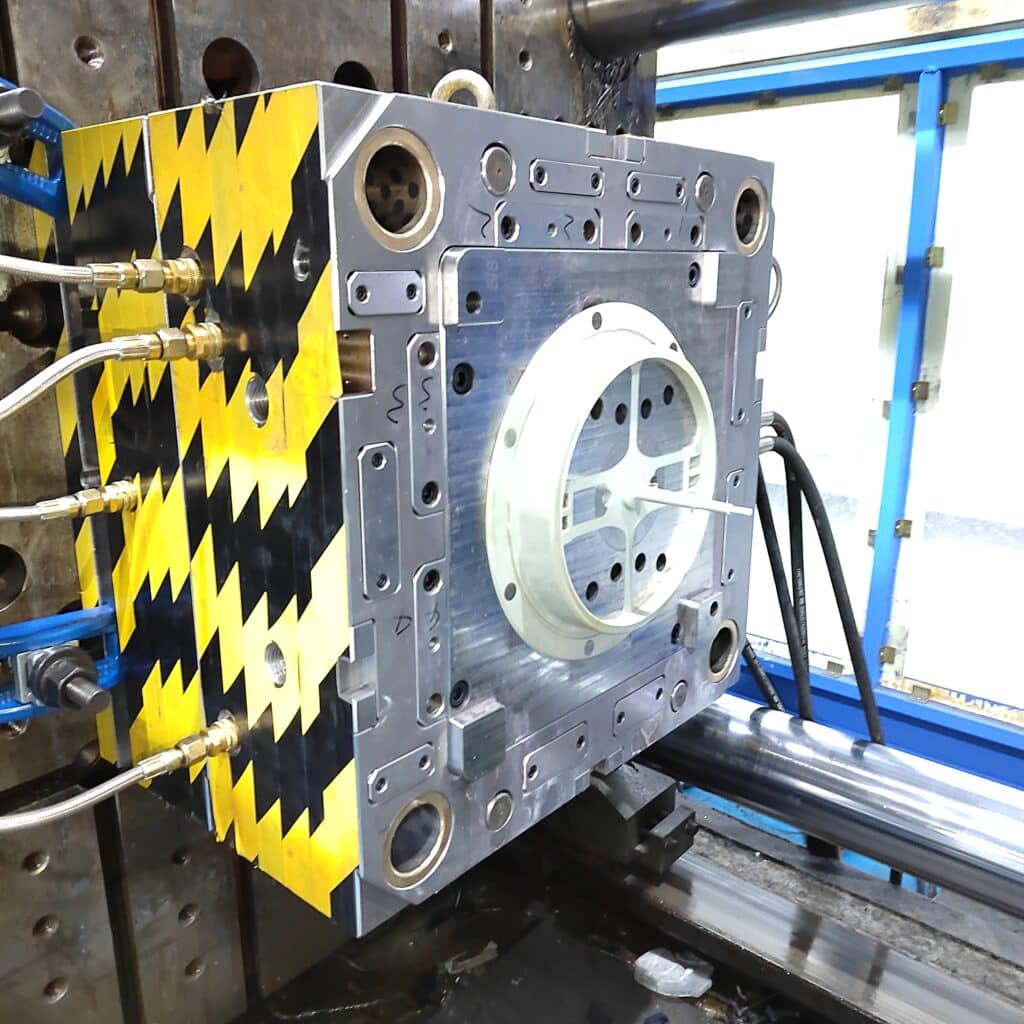

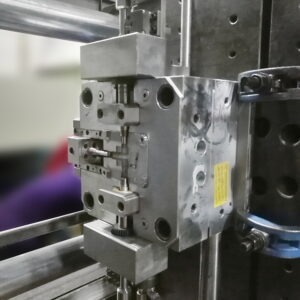

The injection molding tool is a tool for producing plastic products; it is also a tool for giving plastic products a complete structure and precise dimensions. Injection molding is a processing method used for mass production of certain complex shaped parts. Specifically, the heat-melted plastic is injected into the mold cavity at high pressure by an injection molding machine, and then cooled and cured to obtain a molded product. The injection molding tool consists of two parts: a moving mold and a fixed mold, with the moving mold mounted on the moving template of the injection molding machine and the fixed mold mounted on the fixed template of the injection molding machine. During injection molding, the moving mold and the fixed mold are closed to form the pouring system and cavity, and during mold opening, the moving mold and the fixed mold are separated in order to remove the plastic products. In order to reduce the heavy workload of mold design and manufacturing, most of the injection molds use standard mold frames.