Description of injection molding parameters

1、 Drying temperature

Definition: temperature required for drying polymer in advance to ensure molding quality

Functions: 1. Remove water from raw materials 2. Ensure the quality of finished products

Setting principle: 1. The polymer will not decompose or agglomerate (polymerize). 2. The drying time should be as short as possible and the drying temperature should be as low as possible without affecting the drying effect 3. Drying temperature and time vary with different raw materials

Note: 1, A means hot air dryer 2. D indicates dehumidification dryer

2、 Material temperature

Definition: The temperature set on the material pipe to ensure smooth forming

Function: to ensure good polymer plasticization (melt adhesive), smooth mold filling and molding

Setting principle: (1) Do not cause decomposition and carbonization of plastics (2) From the feeding stop to the nozzle, rise in turn (3) The nozzle temperature shall be slightly lower than the front breaking temperature of the barrel (4) The required temperature varies depending on the type of material (5) No bad quality impact on the products

3、 Mold temperature

Definition: surface temperature of the mold cavity contacted by the product

Function: control the cooling rate of the product in the mold cavity and the apparent quality of the product

Setting principles: (1) Consider the properties of polymers (2) Consider the size and shape of the product (3) Consider the mold structure and runner system

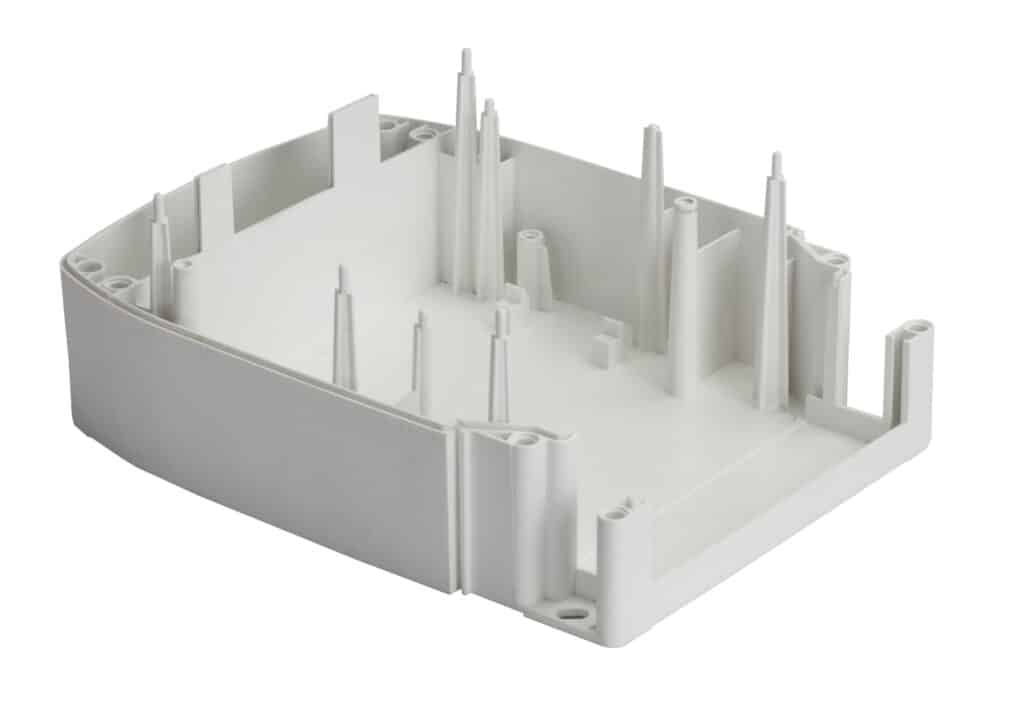

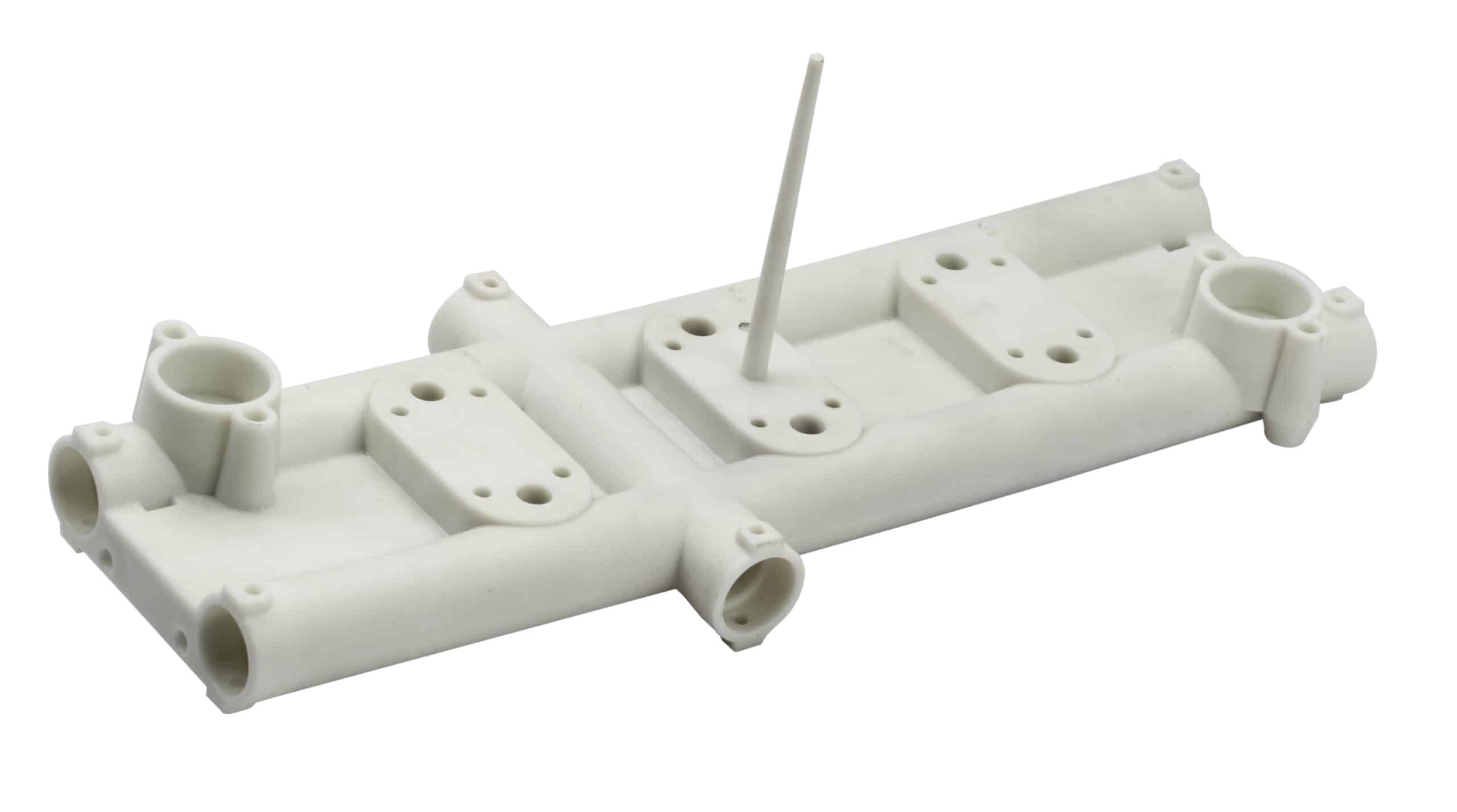

plastic injection part

4、 Injection speed

Definition: Under a certain pressure, the speed at which molten glue is injected into the mold from the nozzle

Function: (1) The increase of injection speed will increase the mold filling pressure (2) Increasing the injection speed can increase the flow length and make the quality even (3) High viscosity during high-speed injection, fast cooling speed, suitable for long process products (4) At low speed, the flow is stable and the product size is stable

Setting principle: (1) Prevent the formwork from being propped and the occurrence of overflow (2) Prevent burning caused by too fast speed (3) On the premise of ensuring the product quality, high speed filling shall be selected as far as possible to shorten the molding cycle

5、 Melting speed

Definition: rotational speed of screw during plasticizing

Function: important parameters affecting plasticizing ability and plasticizing quality. The higher the speed, the higher the melt temperature and the stronger the plasticizing ability

Setting principle: (1) The melting speed is generally adjusted from low to high (2) The rotating speed of the machine with screw diameter greater than 50MM should be controlled below 50RPM, and the machine with screw diameter less than 50MM should be controlled below 100RPM

6、 Ejection pressure

Definition: The maximum pressure at the injection outlet of the screw head is closely related to the oil pressure in the injection cylinder

Function: It is used to overcome the pressure loss of the melt from the nozzle – runner – gate – cavity, so as to ensure that the cavity is filled and the required products are obtained

Setting principle: (1) It must be within the rated pressure range of the injection molding machine (2) Try to use low pressure when setting (3) Try to avoid using high voltage at high speed to avoid abnormal conditions

7、 Back pressure

Definition: The pressure that the plastic builds up in the melting cavity during the plasticizing process

Functions: (1) Increase the specific gravity of the melt (2) Make the melt plasticize evenly (3) Reduce the gas content in the melt and improve the plasticizing quality

Setting principle: (1) The back pressure shall be adjusted according to the nature of plastic raw materials (2) The adjustment of back pressure shall refer to the apparent quality and precision of the product

8、 Clamping pressure

Definition: The clamping force exerted on the mold by the clamping system to overcome the expanding force that separates the mold during the injection and pressure holding stages

Functions: (1) ensure that the mold will not be expanded during injection and pressure holding; (2) ensure the apparent quality of the product (3) Ensure the dimensional accuracy of products

Setting principle: (1) The size of the clamping force depends on the size of the product and the size of the machine (2) Generally speaking, the smaller the clamping force is, the better (3) The clamping force shall not exceed the rated pressure of the machine

9、 Pressure maintaining

Definition: The injection pressure that continues to be applied to the plastic in the mold cavity after the mold cavity is filled with plastic until the gate is completely cooled and closed depends on a relatively high pressure support technology, which is called pressure holding

Function: (1) replenish the material quantity near the gate, and prevent the backflow of the unhardened plastic in the mold cavity under the residual pressure before the gate is cooled and closed, so as to prevent the shrinkage of the parts, avoid shrinkage and reduce the vacuum bubble (2) Reduce the possibility of bursting or bending due to excessive injection pressure

Setting principles: (1) The holding pressure and speed are usually set to 50~60% of the maximum pressure and speed when the plastic fills the mold cavity (2) The holding time is related to the material temperature. The gate with high temperature has a long closing time and a long holding time (3) The pressure holding is related to the projected area and wall thickness of the product, and it takes a long time if the thickness is large (4) Pressure holding is related to the shape and size of gate foot Setting of pressure maintaining switching position, metering length and loosening stroke

10、 Metering stroke

Definition: After plasticization, the screw moves backward under the force of plastic melt from the injection end position to the limit switch during rotation, which is called metering stroke

Function: ensure that there is enough plastic to fill the mold cavity to obtain the required appearance and size of products

Setting principle: (1) The measuring stroke shall be set according to the size of the product and the machine (2) The metering stroke shall not be too large to avoid carbonization caused by excessive plastic injection staying in the material pipe for too long (3) The metering stroke shall not be too small to ensure sufficient metering and avoid mechanical damage to the screw and nozzle. There shall be a buffer of 3~5mm

11、 Ejection stroke

Definition: Change of screw position during injection

Function: combined with speed and pressure to control plastic flow state

Setting principle: (1) The measuring position is determined by the filling volume of the finished product. Generally, 3~5mm impulse is added to this value to determine the final setting (2) The switching point to the second speed is usually switched to the full hot runner and the head position (3) The switching point to the third speed is set with 90% filling degree of the molded product (4) The pressure maintaining switching point is generally set at 90% of the filling degree of the finished product (Note: the above four paragraphs are taken as examples)

12、 Amount of looseness

Definition: After the screw pre molding (metering) is in place, it reverses a certain distance in a straight line. This backward movement is called backward loosening, and the distance of loosening is called the amount of loosening or anti stretching

Function: The function of post loosening is to increase the specific volume of the melt in the metering chamber and decrease the internal pressure to prevent the melt from flowing out of the metering chamber

Setting principles: (1) Set according to the viscosity, relative density of plastic raw materials and the actual situation of products. A large amount of looseness will cause the melt to mix with bubbles and affect the quality of products (2) The setting of loosening amount shall be consistent with screw speed and back pressure (3) For the raw materials with higher viscosity, such as PC materials, the amount of looseness can not be set

13、 Buffer capacity

Definition

Function: (1) Prevent mechanical damage accident caused by contact between screw head and nozzle (2) Control the repeatability of injection volume

Setting principles: (1) The buffer capacity should not be too large or too small. If it is too large, there will be too much residual material, causing pressure loss and material degradation. If it is too small, the purpose of buffer cannot be achieved (2) The buffer amount is generally 3~5mm

14、 Period

Definition: the time from the end of mold opening to the end of mold opening after the next injection cooling is completed

Function: ensure the molding of products and complete cooling and shaping

Setting principle: (1) The cycle shall be as short as possible (2) Shortening cycle must be carried out on the premise of ensuring product quality

15、 Cooling time

Definition: The time required for the product to cool and solidify without deformation after demoulding

Functions: (1) Allow the product to solidify; (2) Prevent the product from deformation

Setting principle: (1) Cooling time is an important part of cycle time, which should be kept as short as possible on the premise of ensuring product quality (2) The cooling time depends on the melt temperature, mold temperature, product size and thickness

16、 Pressure holding time

Definition: To prevent plastic backflow and cooling feeding after injection, continue to apply pressure after injection

Function: (1) Prevent melt backflow after injection molding (2) Feeding effect of cooling shrinkage

Setting principle: (1) Holding time varies with product thickness (2) The holding time varies with the temperature of the molten material. The higher the temperature, the longer the holding time is. The lower the holding time is (3) In order to improve production efficiency, the pressure holding time should be as short as possible on the premise of ensuring the quality

17、 Ejection time

Definition: The time taken for the melt to fill the entire cavity

Function: The injection time is determined by the injection pressure, injection speed, product size and other factors

Setting principle: (1) Make the injection time as short as possible under the condition of ensuring the molding of products (2) Injection time is affected by material temperature, mold temperature and other factors

18、 Melting time

Definition: The time required for the screw to reach the end of metering after the injection is terminated

Function: ensure sufficient glue

Setting principle: (1) Screw speed and back pressure are mutually controlled (2) Don’t let the molten plastic stay in the screw for too long, so as not to cause the plastic to decompose and carbonize under high temperature for a long time

19、 Drying time

Definition: The time required for drying raw materials in advance with drying equipment

Functions: (1) Improve surface luster, bending resistance and tensile strength, and avoid internal cracks and bubbles (2) Improve plasticizing ability and shorten molding cycle (3) Reduce moisture and moisture in raw materials

Setting principle: (1) The drying time varies with the raw materials (2) The drying time should be set appropriately. If it is too long, the drying efficiency will be reduced or even the raw materials will be caked. If it is too short, the drying effect will be poor