How to deal with bubbles in injection molding

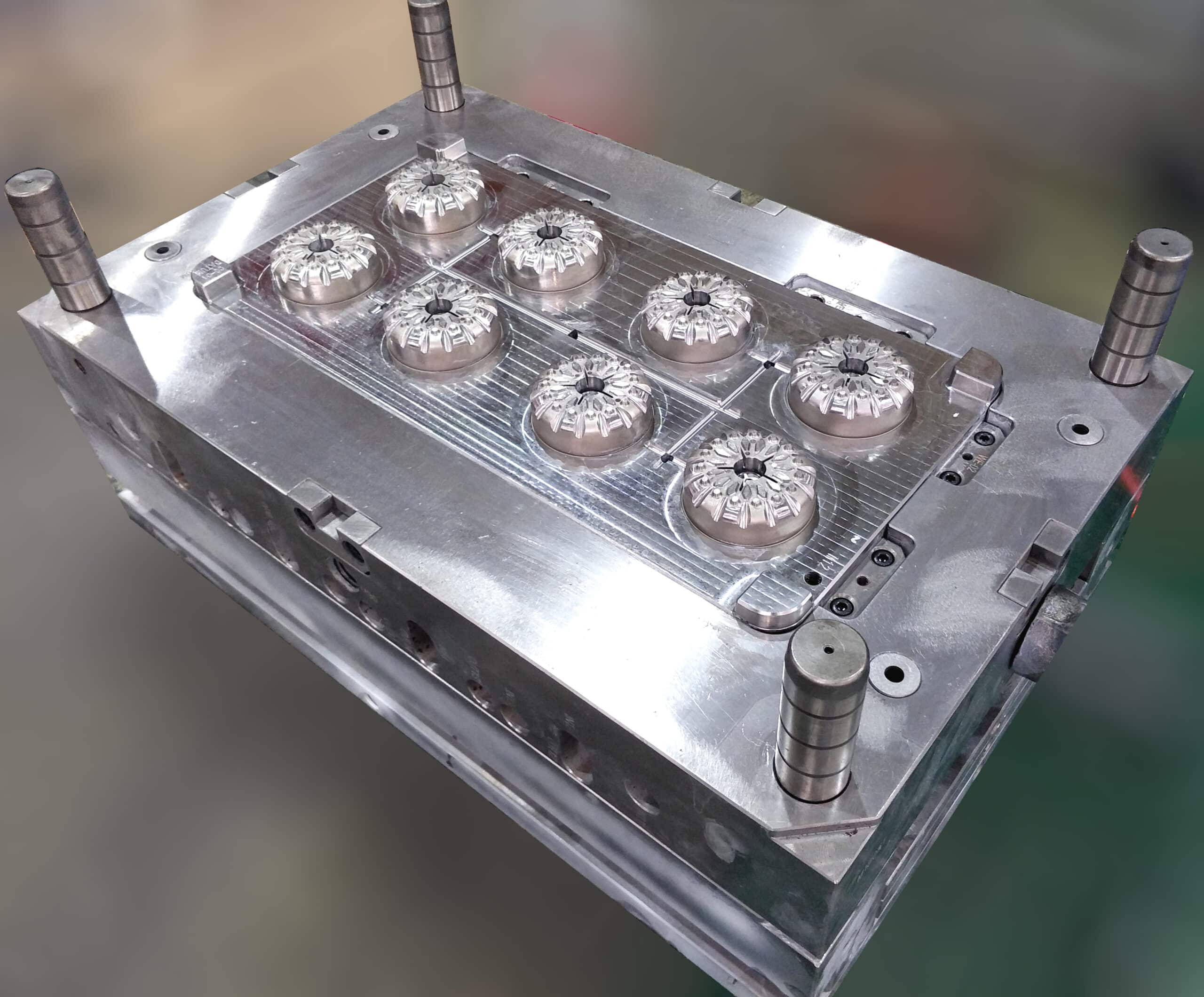

plastic injection mold

According to the causes of bubbles, the countermeasures are as follows:

1) When the wall thickness of the product is large, the cooling speed of its outer surface is faster than that of the center part. Therefore, as the cooling proceeds, the resin in the center part shrinks while expanding to the surface, resulting in insufficient filling in the center part. This condition is called a vacuum bubble. The solutions mainly include:

a) Determine reasonable gate and runner size according to wall thickness. Generally, the gate height shall be 50%~60% of the product wall thickness.

b) Until the gate is sealed, a certain amount of supplementary injection material is reserved.

C) The injection time should be slightly longer than the gate sealing time.

d) Reduce injection speed, increase injection pressure,

e) Use materials with high melting viscosity.

2) The main solutions to the bubbles caused by the generation of volatile gases are:

a) Fully pre dry.

b) Reduce the temperature of resin to avoid generating decomposition gas.

3) Bubbles caused by poor fluidity can be solved by increasing the temperature of resin and mold and increasing the injection speed.