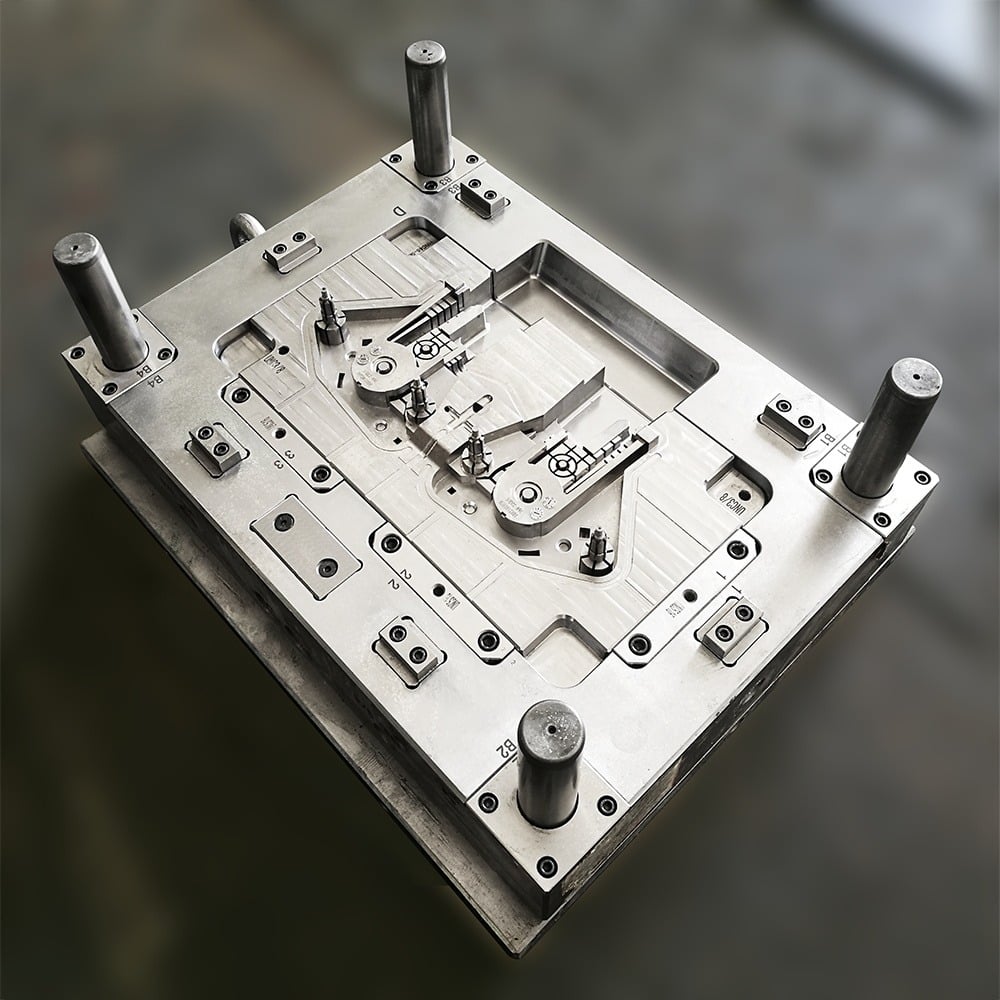

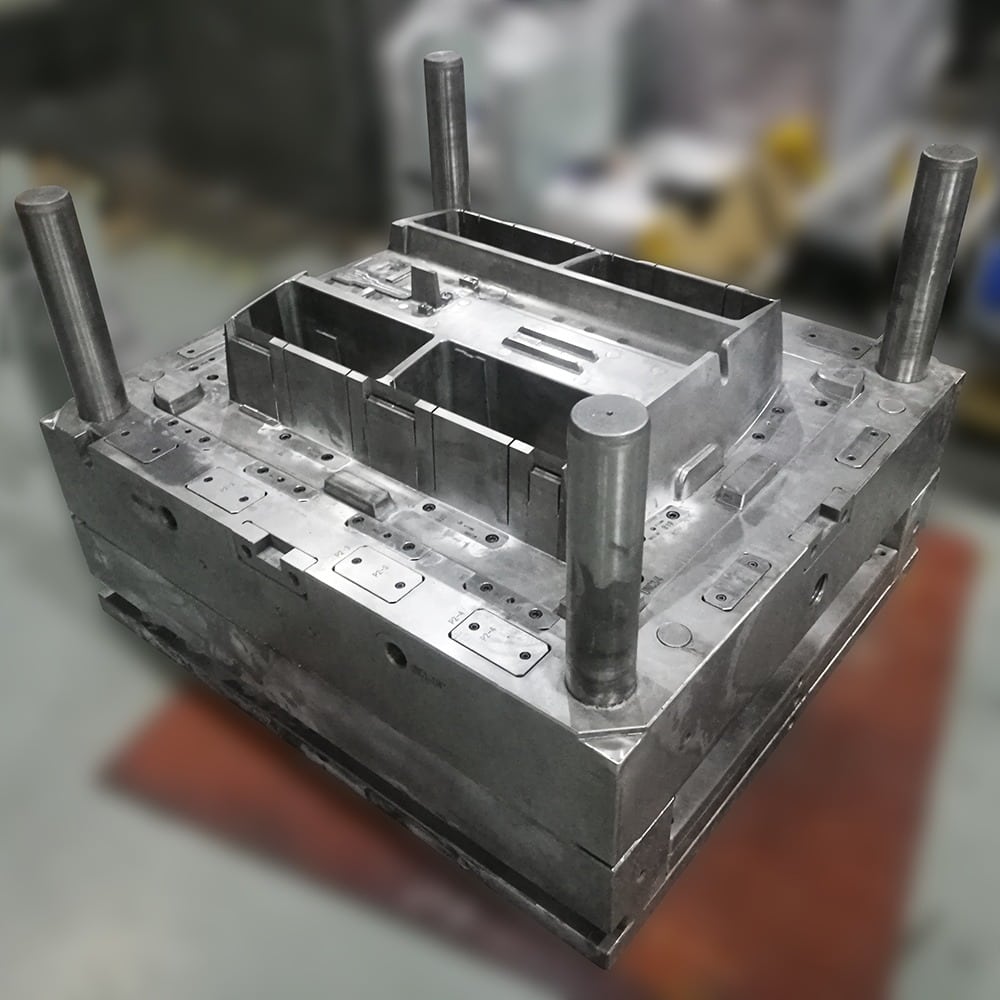

How to do a good job in surface treatment during mold manufacturing?

Although the surface of plastic coated injection mold manufacturing is plastic coated, in some cases, surface treatment is also required, on the one hand, to protect the castings from corrosion, on the other hand, it can also play a decorative role to make the appearance more beautiful. Injection mold surface treatment manufacturers introduce the following surface treatment processes for common zinc alloy castings.

electroplate. The newly polished zinc alloy casting looks like chrome plated, but it will soon lose its luster. The common electroplating process of zinc alloy castings is nickel plating on the bottom coating of copper and then chromium treatment. In addition, zinc alloy castings can also be directly plated with chromium, which can improve the hardness and wear resistance of castings, reduce friction coefficient and improve corrosion resistance. Painting. Zinc alloy can be coated with various paints. Before painting, the workpiece shall be treated with phosphate or chromate solution. For some cheaper parts, acrylic paint with weak adhesion and acid corrosion components can be used. For parts with high corrosion resistance requirements, Z should use epoxy resin paint or various amino paints and bake them after painting.

Metal spraying. The metal spraying method is to coat a thin metal film on the surface of the processed parts under high vacuum. Metal spraying can simulate the appearance of copper, silver, brass, gold, etc. This process is mostly used for die castings. If the surface defects can be covered by painting primer after degreasing, the workpiece to be treated does not need polishing. After baking at low temperature, aluminum vapor will be deposited on the part to form a film under vacuum. After the second spraying of varnish, the silver white paint layer can be obtained by baking, and can be dyed into any color. Anodic oxidation treatment. The anodizing treatment of zinc alloy castings is carried out in the anodizing treatment solution at a voltage not exceeding 200V. The surface of the castings after treatment is porous and can be sealed in a heated dilute solution of sodium silicate or with organic paint.

Electroplating surface treatment of injection mold parts is a very common zinc alloy treatment process. The zinc alloy electroplating process is nickel plating on the copper base coating, and then chromium treatment. In addition, zinc alloy castings can also be directly chrome plated to improve the hardness and wear resistance of the castings, reduce the friction coefficient and improve the corrosion resistance.

The metal spraying surface treatment of injection mold manufacturing parts is to coat a very thin metal film on the surface of the treated parts under high vacuum. Metal spraying treatment of injection mold can simulate the appearance of copper, silver, brass, gold, etc. This process is mostly used for die castings. If the surface defects can be covered by painting primer after degreasing, the workpiece to be treated does not need polishing. After baking at low temperature, the aluminum vapor is deposited on the part under vacuum to form a film. After the second spraying of varnish, the silver white paint layer can be obtained by baking, and can be dyed into any color.