Injection mold maintenance and mold repair are more important. The more times of maintenance, the shorter the mold life. On the contrary, the better the maintenance, the longer the mold life. Injection mold is just like a human body. If you do not maintain it regularly or reasonably, there will be various problems in the production, leading to no guarantee of product quality. In addition to the maintenance of injection molds, we need to know more about the maintenance of injection molding abrasives. General injection mold maintenance is divided into three major items:

1. Maintain the injection mold when it is not in production.

2. Maintenance of injection mold during production.

3. Post production maintenance of injection mold

How to maintain the injection mold after production?

Injection mold is the most important molding equipment for processing injection products, and its quality is directly related to the quality of products. Moreover, because the mold occupies a large proportion in the production cost of injection molding processing enterprises, its service life directly affects the cost of injection molding products. Therefore, it is an important task for injection molding enterprises to reduce costs and increase efficiency to improve the quality of injection molds, maintain and extend their service life.

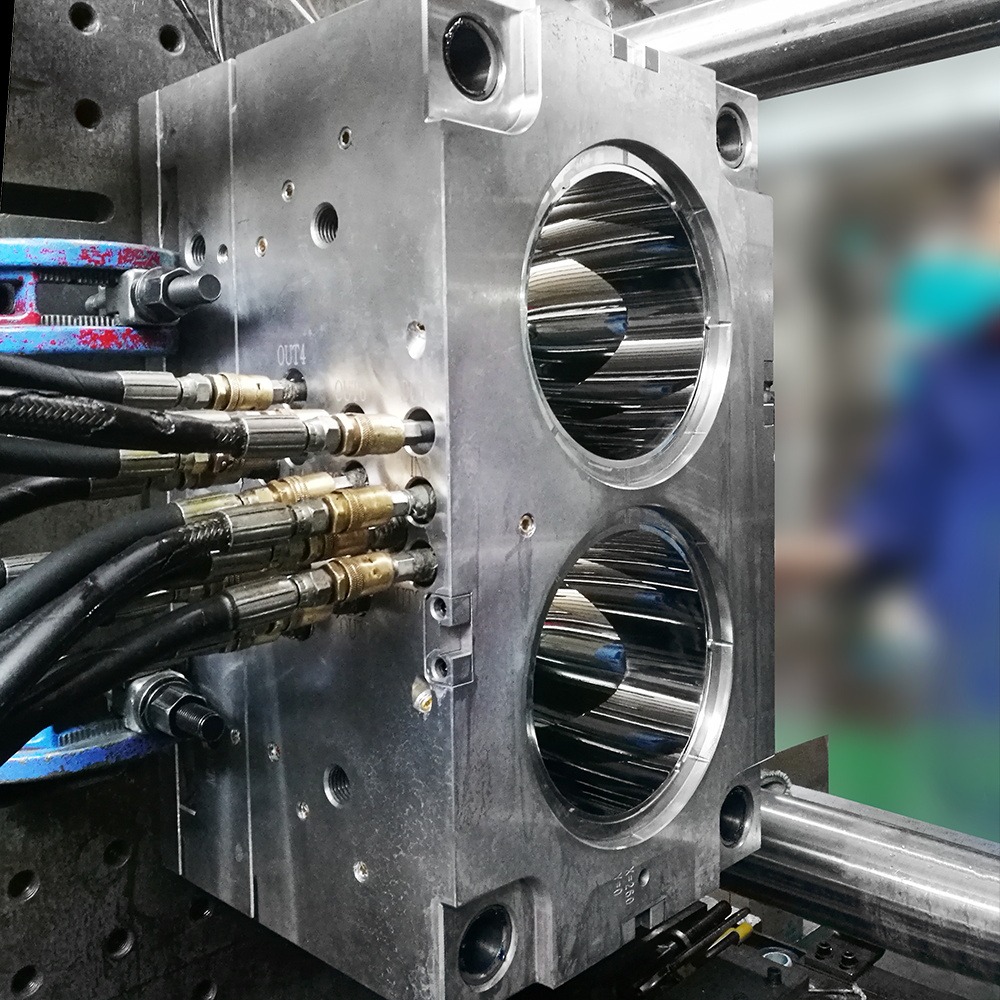

Due to the large variety of products, mold replacement is frequent in injection molding product processing enterprises. After completing a production cycle, the mold is generally stored in the warehouse until the next production cycle comes. However, some processing enterprises do not pay enough attention to mold preservation, which leads to corrosion, surface finish decline and other phenomena during the mold preservation period, resulting in product quality decline, high scrap rate, and some molds are even difficult to reuse, which requires a large amount of investment in new molds, causing huge waste.

The data shows that the use and maintenance account for 15%~20% of the factors affecting the service life of the mold. The service life of the injection mold can generally reach 800000 times. Some well maintained molds abroad can even be extended by 2~3 times. However, due to neglect of maintenance, the service life of injection mold in domestic enterprises is relatively short, which is only 1/5~1/3 of that in foreign countries. Due to the short service life of the die, the steel processing man hours and energy waste, as well as the impact on product quality, bring losses of billions of yuan every year.

Therefore, the maintenance of injection molds is very important, as follows:

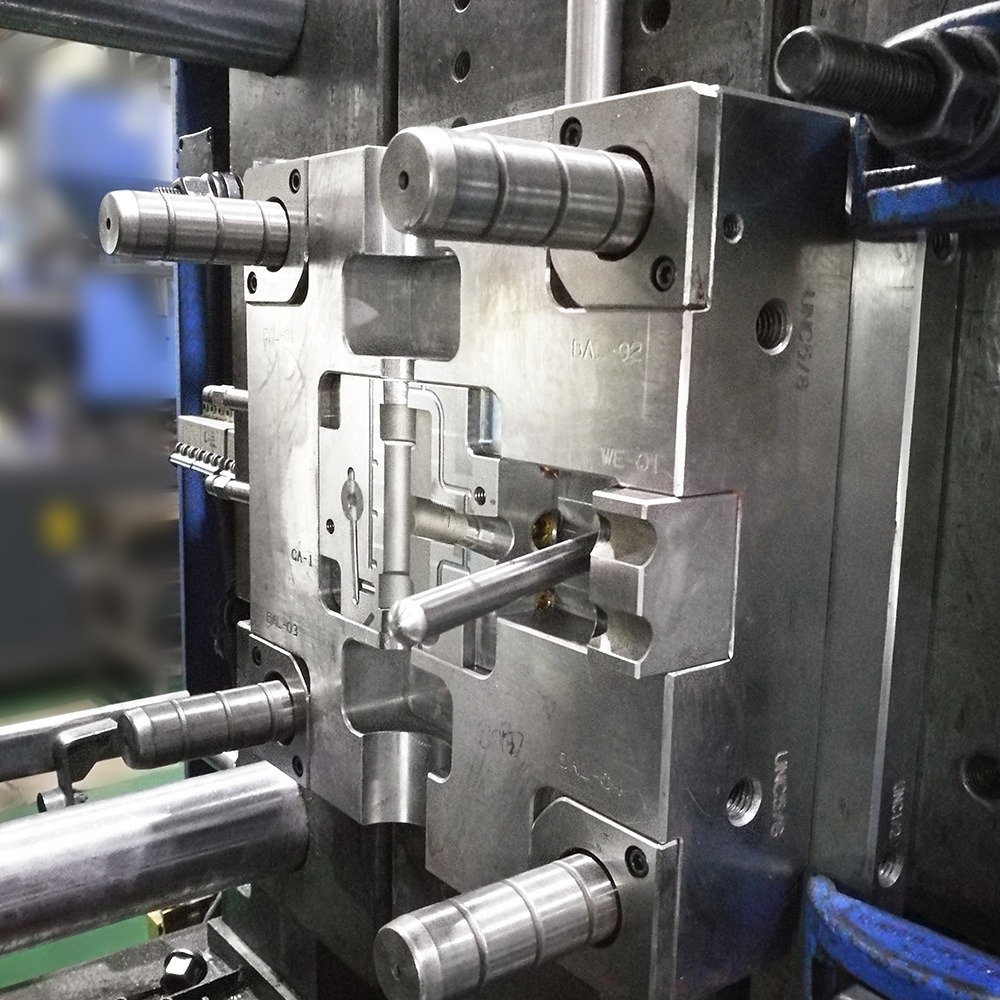

1. The processing enterprise shall first provide each pair of molds with a resume card to record and count in detail their use, care (lubrication, cleaning, rust prevention) and damage, so as to find out which parts and components have been damaged and the degree of wear, so as to provide information on finding and solving problems, as well as the molding process parameters of the mold and the materials used for the product, so as to shorten the trial run time of the mold and improve the production efficiency.

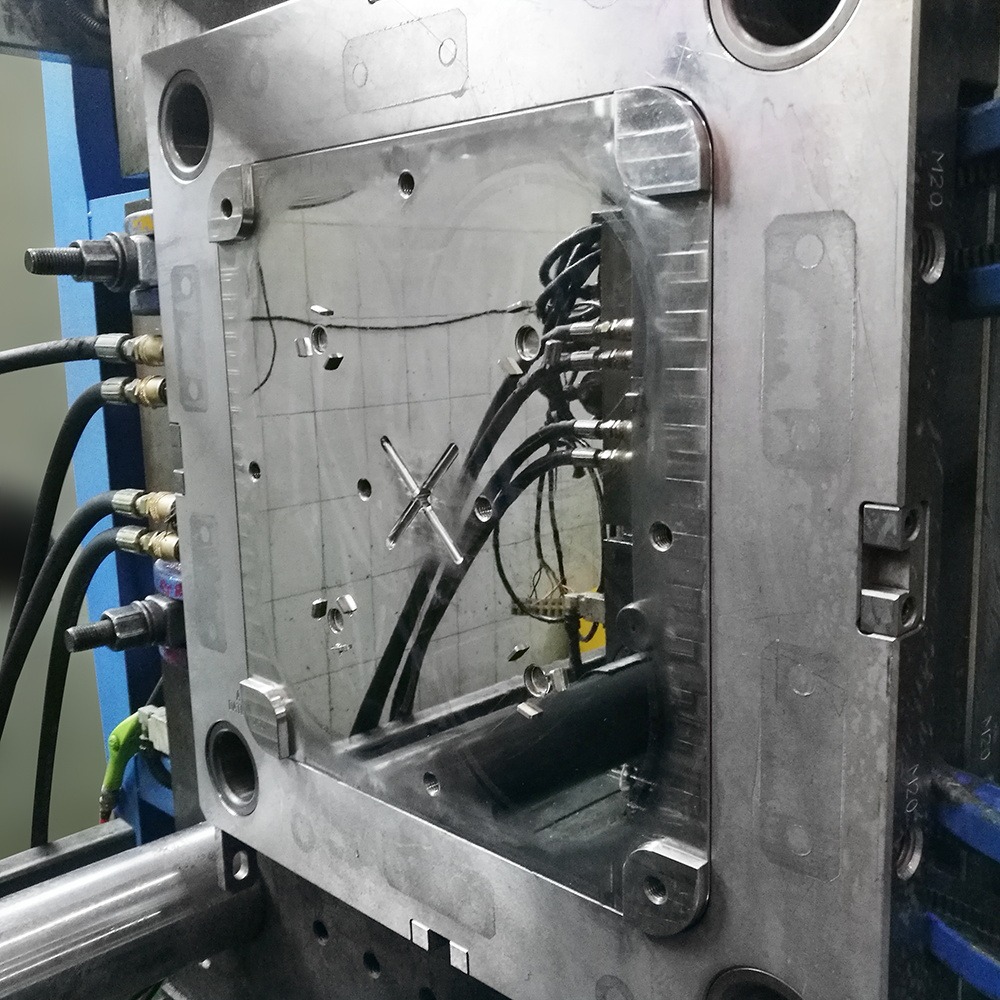

plastic injection molding

2. The processing enterprise shall test various performances of the mold under the normal operation of the injection molding machine and mold, and measure the size of the last molded plastic part. Through this information, the existing state of the mold can be determined, and the damage of the cavity, core, cooling system and parting surface can be found out. According to the information provided by the plastic part, the damage state of the mold and maintenance measures can be judged.