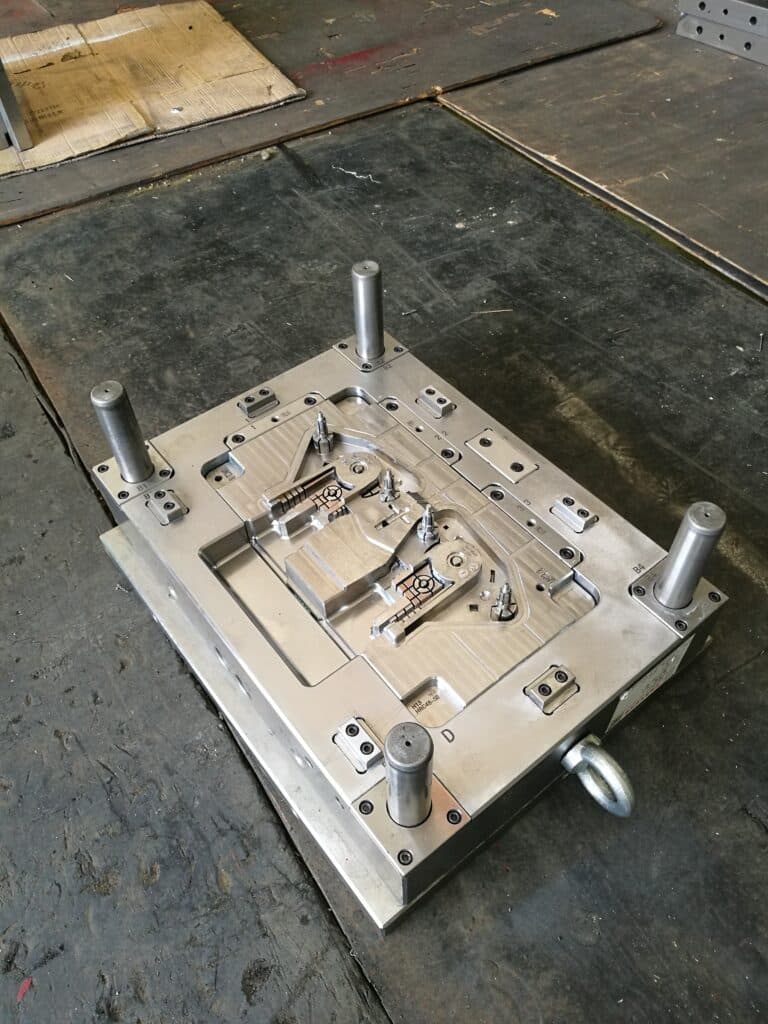

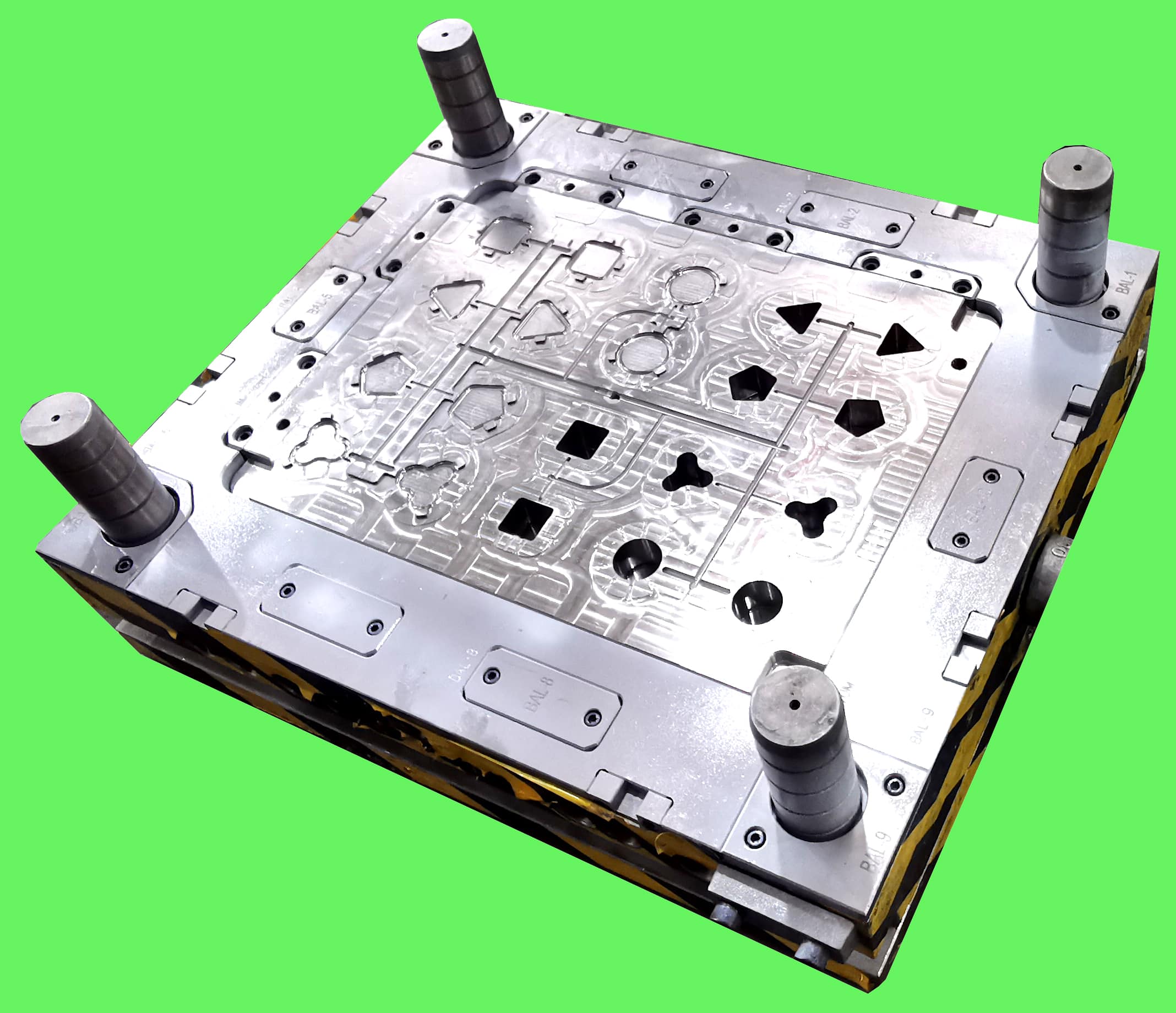

Injection Mold Maintenance Plan

1、 Inspection and maintenance during mold installation

1. Clean the upper and lower surfaces of the injection mold before installing the mold to ensure that the installation surface of the injection mold is correctly matched with the working surface of the press.

2. After the mold is installed, open the mold, and clean the mold guide mechanism and mold cavity surface to ensure the quality of the parts.

3. Lubricate or grease the sliding parts of the die.

4. Check and maintain the side guard, and clean the punching waste channel and hole.

5. Check the safety parts such as the safety side pin and safety screw of the mold, and repair and replace them in time if any problems are found.

2、 Maintenance in production

1. Frequently observe and feel the use status of the mold during production. If any abnormality is found, stop the machine for inspection immediately and eliminate it in time. Production can be carried out after troubleshooting.

3、 Maintenance after production

1. After production, the injection mold shall be comprehensively inspected.

2. Fully clean the injection mold, clean up the waste and sundries in the mold, and ensure that there is no waste in the waste box.

3. Feedback the problems found in the use of injection mold truthfully, and make records in the handover form or notify the repair personnel to repair.

4、 Maintenance of injection mould for a long time

For the injection mold that has been placed for a long time, maintenance should be arranged every two months. The method is to open the injection mold to remove dust and rust, and to provide oil coating for all parts of the injection mold