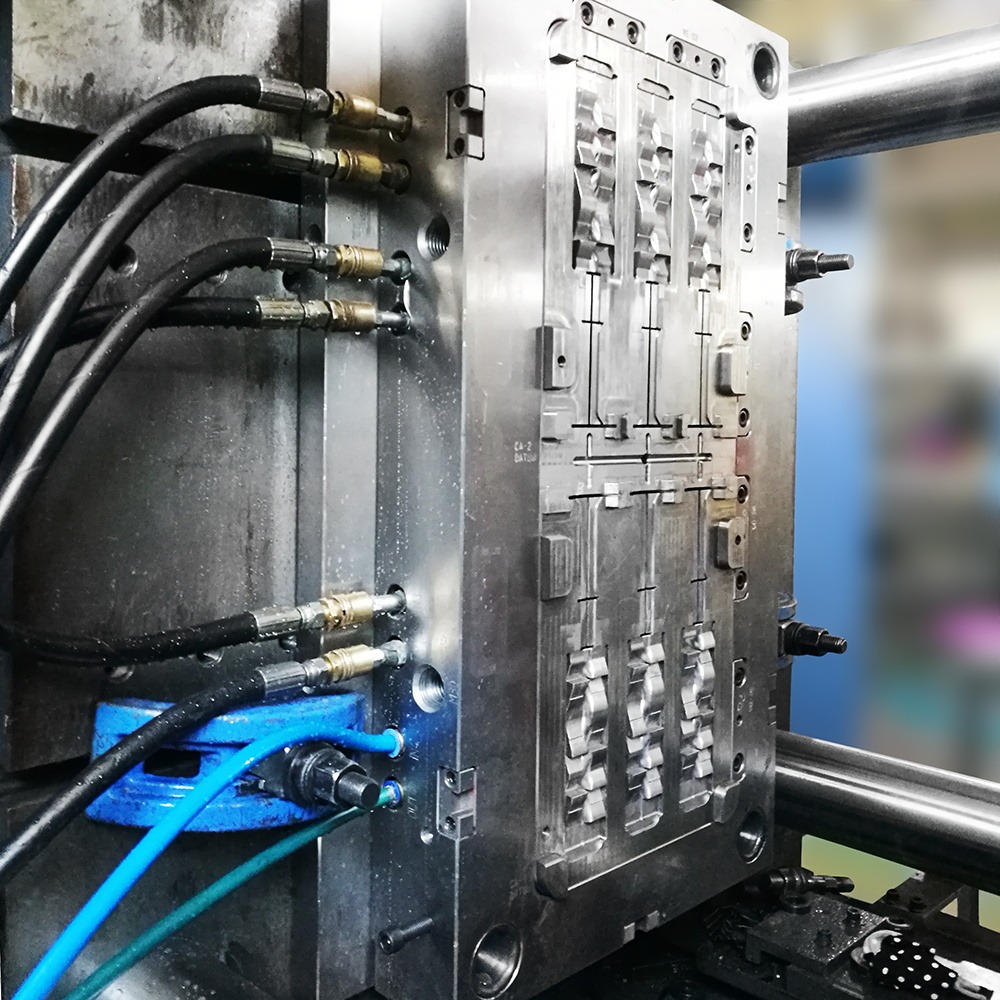

Process of mold making

1. Sawing machine blanking

2. Milling machine processing

3. Outsourced vacuum heat treatment

4. Grinding machine processing

5. CNC machining (programming)

6. W/C (wire cutting)

7. EDM

8. Polishing

9. The fitter’s assembly is OK and the mold is tested

plastic injection mold

Key inspection points after die assembly

1. Check whether all parts have been installed according to the list.

2. Check whether each component is marked with an obvious distinguishing mark according to the drawing.

3. Check whether each part that needs to move on the injection molding machine table is lubricated and smooth.

Check whether the position and direction of each component are correct according to the drawings or 3D drawings. After blowing the parting surface of the mold with an air gun, make sure that the mold is smoothly closed, and then try the mold.

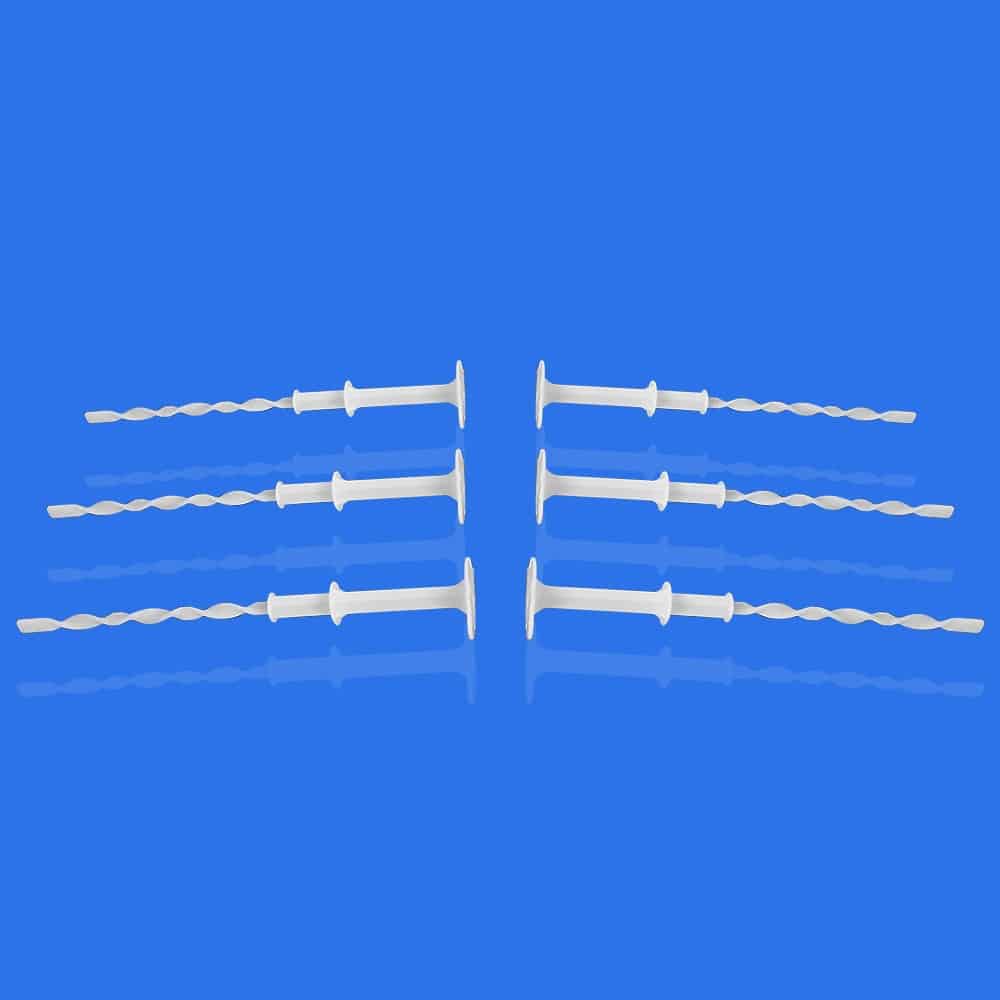

plastic injection mold products

Key points for attention in die production

1. Check the mold condition.

2. Check and set the safety device.

3. Let the operators understand the problems that may occur in the process, including (safety, mold action, machine, product limit).