Reasons for fusion joints in injection molded products

When molten plastic meets in multiple strands in the cavity due to holes in inserts, areas with discontinuous flow rates, or areas where the flow of mold filling material is interrupted, linear fusion joints are created because of incomplete fusion. In addition, fusion joints are also generated in the case of gate injection filling, and the strength of the fusion joints is poor. The main reasons are analyzed as follows.

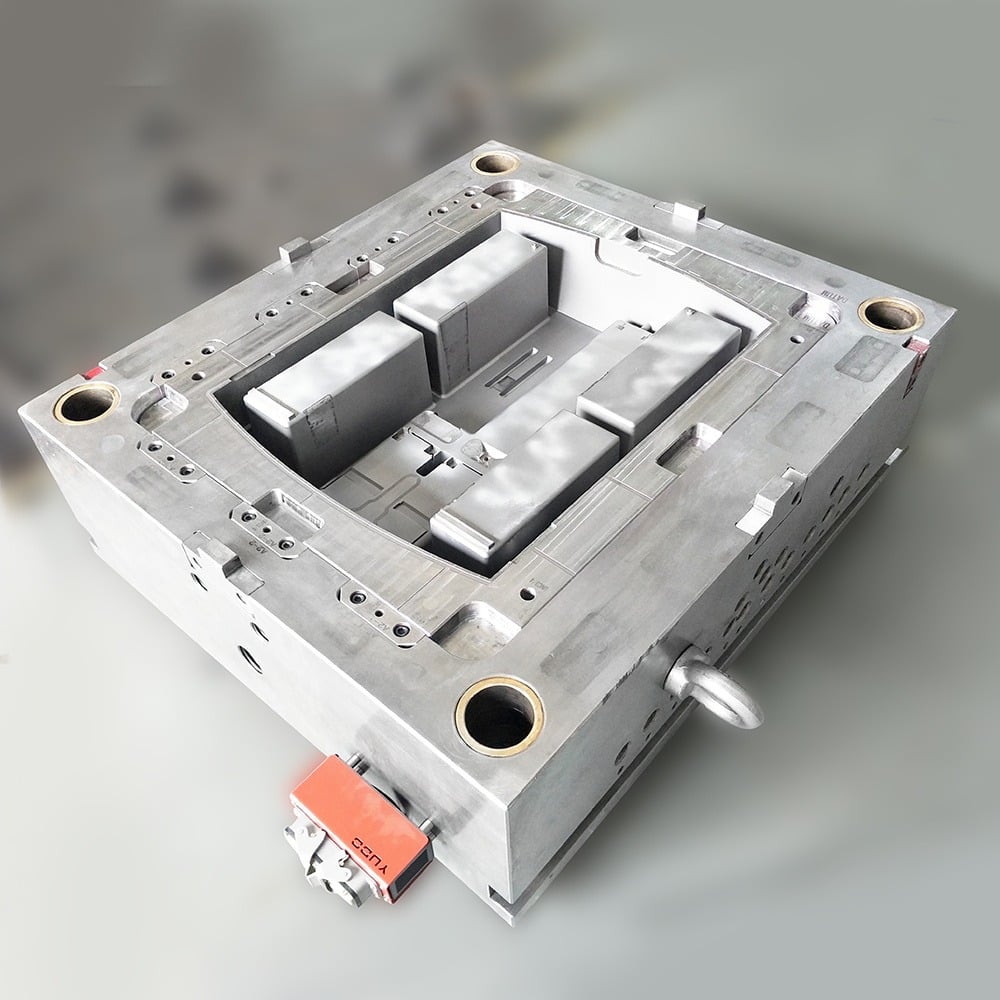

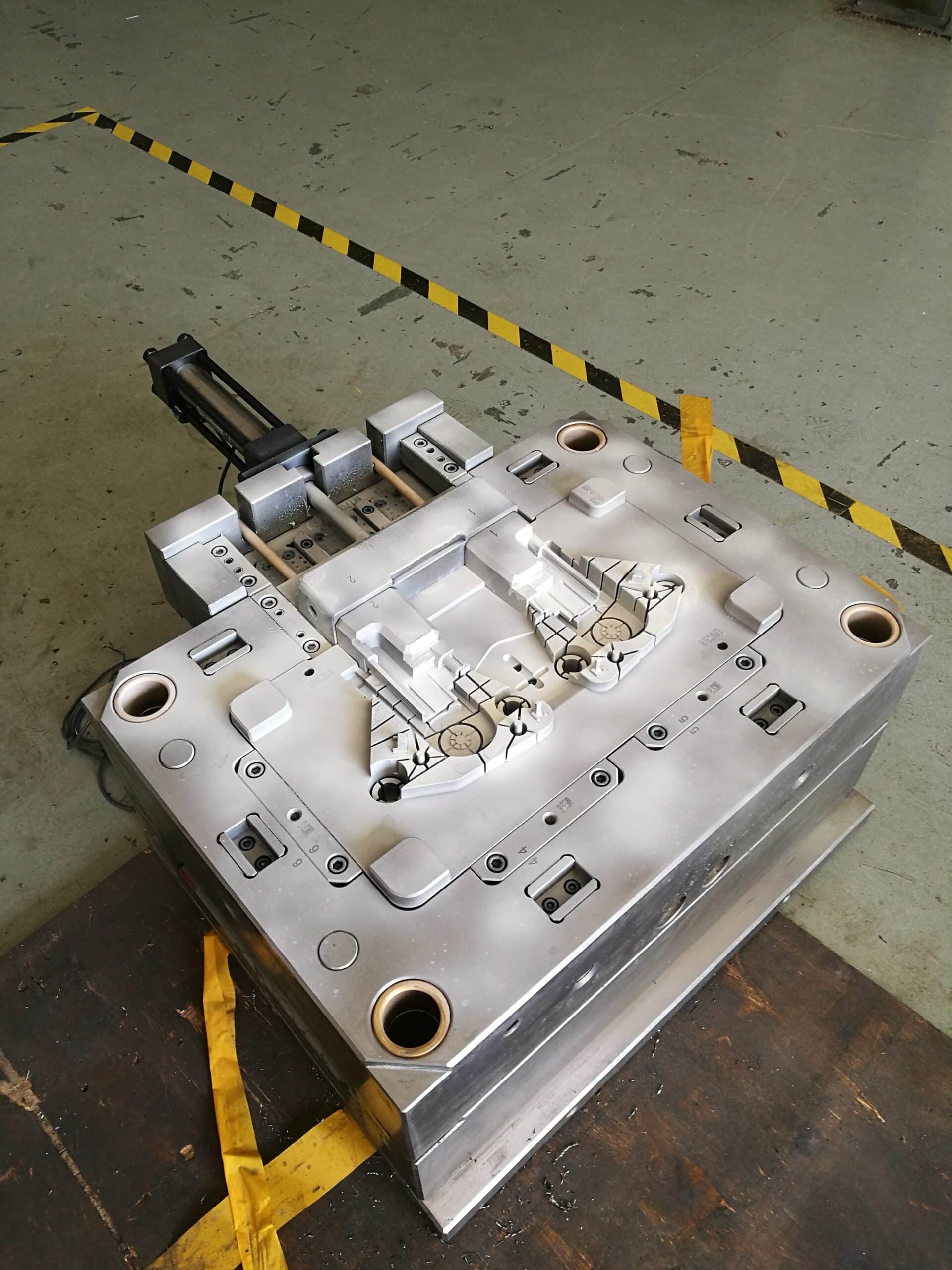

Brass Insert Molding for Auto Parts

1. Processing.

(1) Injection pressure, speed is too low, barrel temperature, mold temperature is too low, resulting in premature cooling of the molten material entering the mold and fusion joints.

(2) When the injection pressure and speed are too high, there will be jetting and fusion seam will appear.

(3) The rotational speed should be increased to increase the back pressure so that the plastic viscosity decreases and the density increases.

(4) Plastic should be dried well, recycled material should be used sparingly, too much mold release agent or bad quality will also appear fusion seam.

(5) Reduce the clamping force to facilitate exhaust.

2. Mold aspects.

(1) Too many gates in the same cavity, should be reduced or set symmetrically, or set as close to the fusion joint as possible.

(2) Poor exhaust at the fusion joint, an exhaust system should be opened.

(3) The sprue is too large, the casting system is not properly sized, and the gate should be opened to avoid the melt flowing around the insert hole, or to use as few inserts as possible.

(4) The wall thickness changes too much, or the wall thickness is too thin, should make the wall thickness of the parts even.

(5) If necessary, a fusion well should be opened at the fusion joint to make the fusion joint off the part.

3. Plastics.

(1) For poor fluidity or heat-sensitive plastics should be added appropriately lubricants and stabilizers.

(2) The plastic contains many impurities, if necessary, to change the quality of plastic.