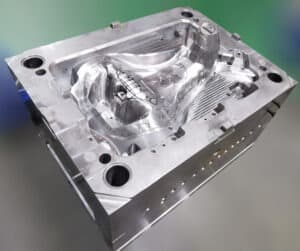

Common Finishing Process In Die Manufacturing

Common finishing process in die manufacturing The finishing process of mold manufacturing directly affects the quality of a mold part, so it is very important to control the finishing. In the finishing stage, electric machining, grinding and bench work are generally used. In this stage, many technical parameters should be well controlled. 1. Part heat treatment The internal stress needs to be controlled to ensure the dimensional stability of the parts in the processing process