What Is The Injection Molding Process And Principle?

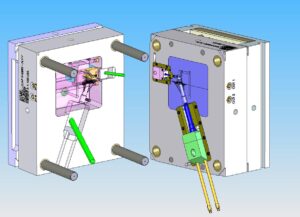

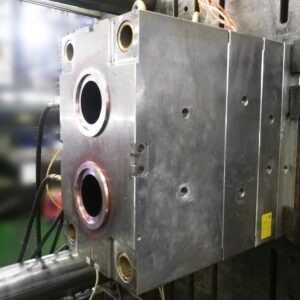

What is the injection molding process and principle? The basic principle of injection molding is to add granular or powdery raw materials to the hopper of the injection molding machine. The raw materials are melted and become liquid after heating. Promoted by the screw rod or piston rod of the injection molding machine, the raw materials enter the shell mold through the injection nozzle and the gating system software of the die-casting mold, and the