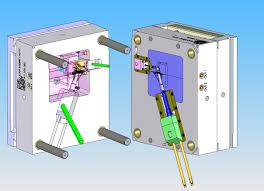

Process characteristics of two-shot injection molding

Process characteristics of two-shot injection molding Two shot injection molding refers to the molding method of injecting two kinds of plastics with different colors into the same mold. It can make the plastic parts appear two different colors, and can make the plastic parts appear regular patterns or irregular moire patterns, so as to improve the practicality and beauty of the plastic parts. Two color injection molding is a process of injection molding. It