The four main development directions of high precision injection mold processing factory

1. whether the precision of high precision injection mold processing can meet the requirements.

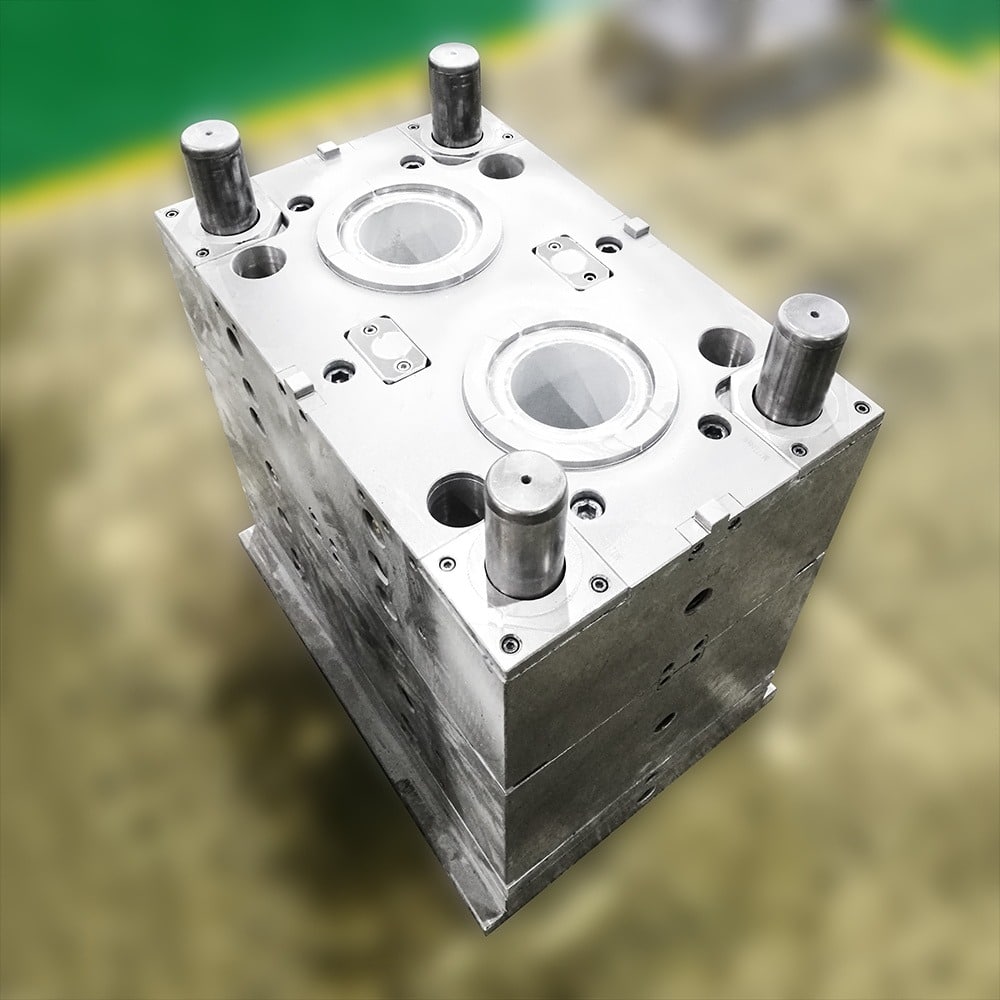

With decades of industrial development, China’s high precision injection mold processing has also gradually developed and matured. To do high precision injection mold processing, the main influencing factors, one is high precision injection mold processing machinery and equipment, and one is high technology personnel.

2. High automatic precision mold processing technology.

High precision injection mold processing parts of the gradual standardization of the level of improvement, precision injection mold output power is also higher and higher, and in this whole process, the requirements of high precision injection mold design staff will be higher and higher, enterprise automation will also be higher and higher

3. New high precision injection molding tool processing follow the continuous development of technological improvement projects.

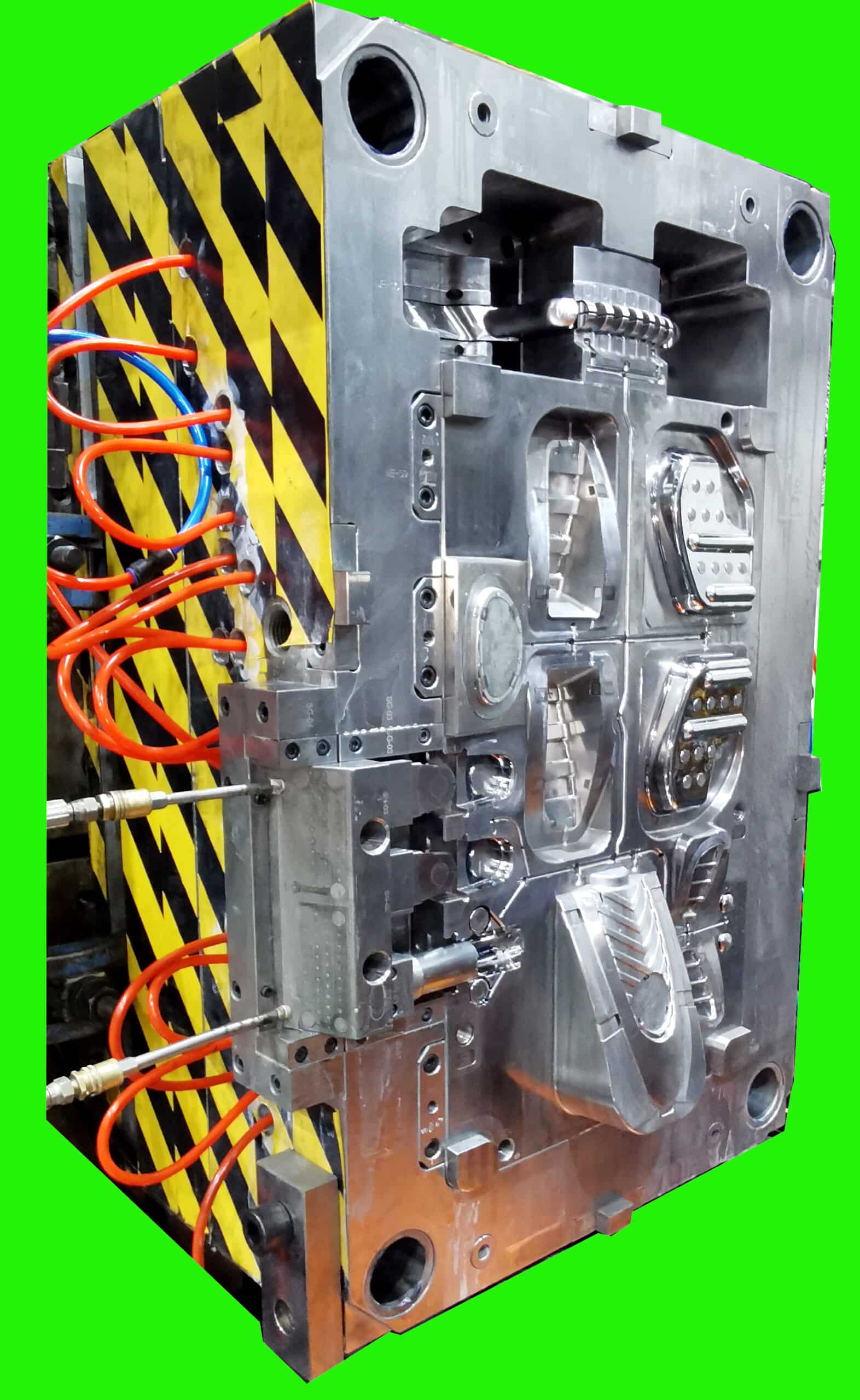

This kind of is the new opportunity and meet in the work of high precision injection molding mold processing, is the mold design mold opportunity and meet, mastered this new mold design program and make technical mold factory, will have a large number of fully automatic. Mold, always rely on technicality and quality speech in the work!

4. commodity research and development and mold combination of this development trend is also certain.

One can serve as all the goods from the appearance to the institution, and then to the high precision injection mold design, to mold production processing, mold production, a series of goods assembled in a new upgrade of the work of the position. Become the inevitable management center of the production industry.