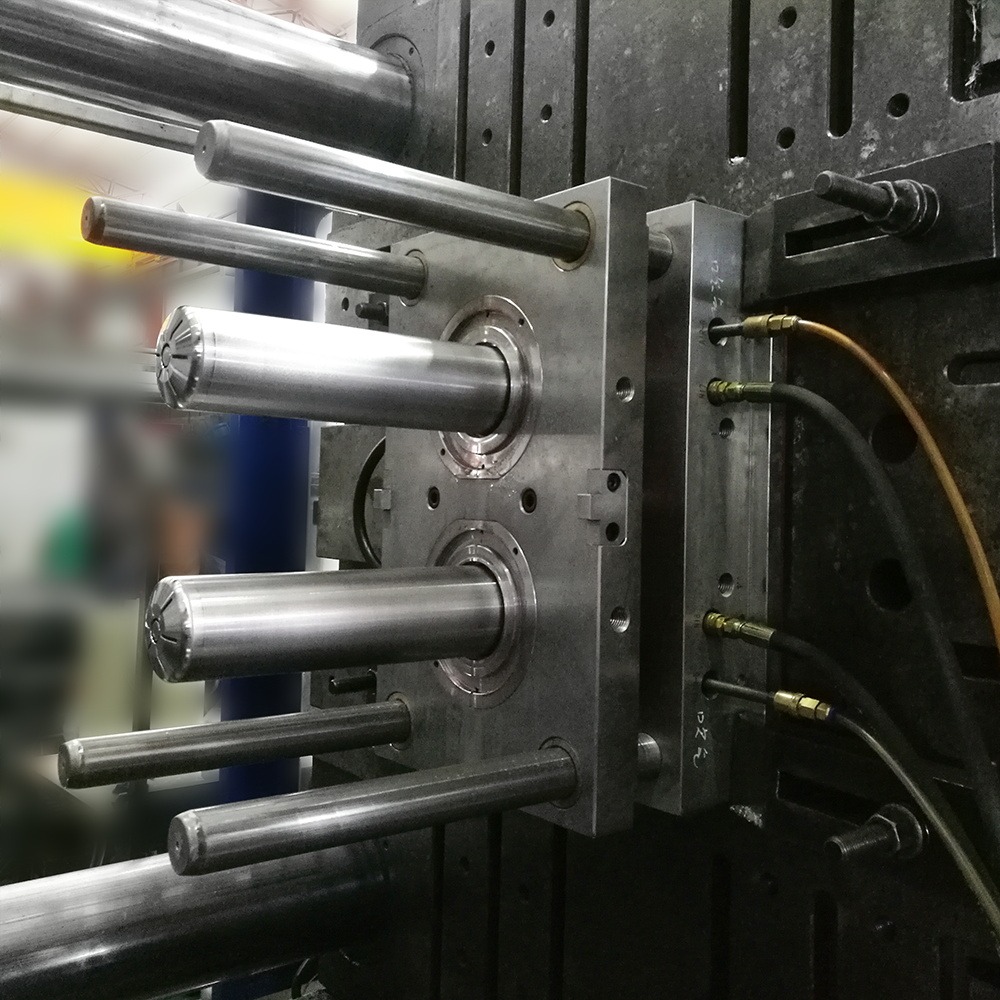

Hot runner system, also known as hot runner system, is mainly composed of hot runner sleeve, hot runner plate and temperature control electric box. The common hot runner system includes single point hot runner and multi-point hot runner. Single point hot gate is used to directly inject molten plastic into the mold cavity with a single hot gate sleeve, which is applicable to the plastic mold with a single cavity and single gate; The multi-point hot gate is used to branch the molten material into each sub hot gate bushing through the hot runner plate and then enter the mold cavity. It is suitable for single cavity multi-point feeding or multi cavity mold.

Advantages of hot runner system

1. There is no need for post processing, so the whole forming process is fully automated, saving working time and improving work efficiency.

2. Low pressure loss. The temperature of the hot runner is equal to that of the injection molding machine nozzle, which avoids the surface condensation of raw materials in the runner and reduces the injection pressure loss.

3. Reuse of nozzle material will degrade the plastic performance, while the use of hot runner system without nozzle material can reduce the loss of raw materials, thus reducing the product cost. In the mold cavity, the temperature and pressure are uniform, the stress of the plastic parts is small, and the density is uniform. Under a small injection pressure, a better product than the general injection molding system can be molded in a short molding time. For transparent parts, thin parts, large plastic parts or plastic parts with high requirements, it can show its advantages and produce larger products with smaller models.

4. The hot nozzle adopts standardized and serialized design, and is equipped with various nozzle heads for selection, with good interchangeability. The specially designed and processed electric heating ring can achieve uniform heating temperature and long service life. The hot runner system is equipped with hot runner plates, temperature controllers, etc., with exquisite design, various types, convenient use, stable and reliable quality.

Shortcomings in the application of hot runner system

1. The closing height of the overall mold is increased, and the overall height of the mold is increased due to the installation of hot runner plates.

2. The heat radiation is difficult to control, and the biggest problem of the hot runner is the heat loss of the runner, which is a major issue to be solved.

3. There is thermal expansion, and thermal expansion and cold contraction are problems we should consider when designing.

4. The increase of mold manufacturing cost and the high price of standard accessories of hot runner system affect the popularity of hot runner molds.

Facebook

Twitter

LinkedIn

Pinterest

Telegram

WhatsApp