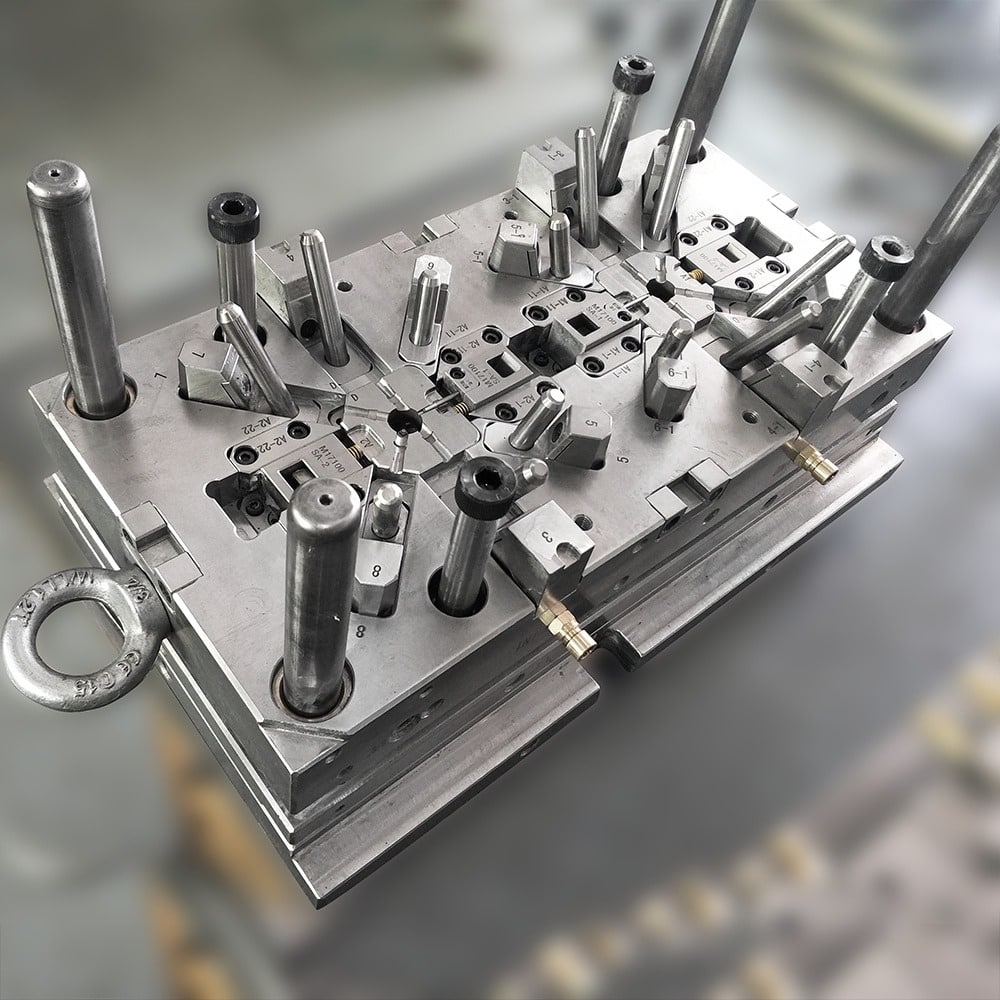

Injection mold is composed of several steel plates and various parts, basically divided into:

A Forming device (female die, male die)

B Positioning device (guide post, guide sleeve)

C Fixing device (I-shaped plate, code mold pit)

D Cooling system (water delivery hole) E Constant temperature system (heating pipe, generator)

F Flow passage system (nozzle hole, flow passage groove, flow passage hole)

G Ejection system (ejector pin, ejector rod)

The molds can be divided into three categories according to the different types of gating systems:

1. Gate mold: the runner and gate are on the parting line and demoulded together with the product when opening the mold. The design is the simplest, the processing is easy, and the cost is low. Therefore, more people use the gate system to operate.

2. Fine nozzle mold: the runner and gate are not on the parting line, and are generally directly on the product. Therefore, a group of nozzle parting lines should be designed. The design is more complex, and the processing is more difficult. Generally, the fine nozzle system should be selected according to the product requirements.

3. Hot runner mold: The structure of this kind of mold is basically the same as that of the fine nozzle. The biggest difference is that the runner is located in one or more hot runner plates and hot pump mouths with constant temperature, and there is no cold material demoulding. The runner and gate are directly on the product. Therefore, the runner does not need demoulding. This system is also called a nozzle free system, which can save raw materials. It is applicable to the situation where raw materials are expensive and product requirements are high. It is difficult to design and process, and the mold cost is high.