Eight Maintenance Points of Injection Molding Machine Manipulator

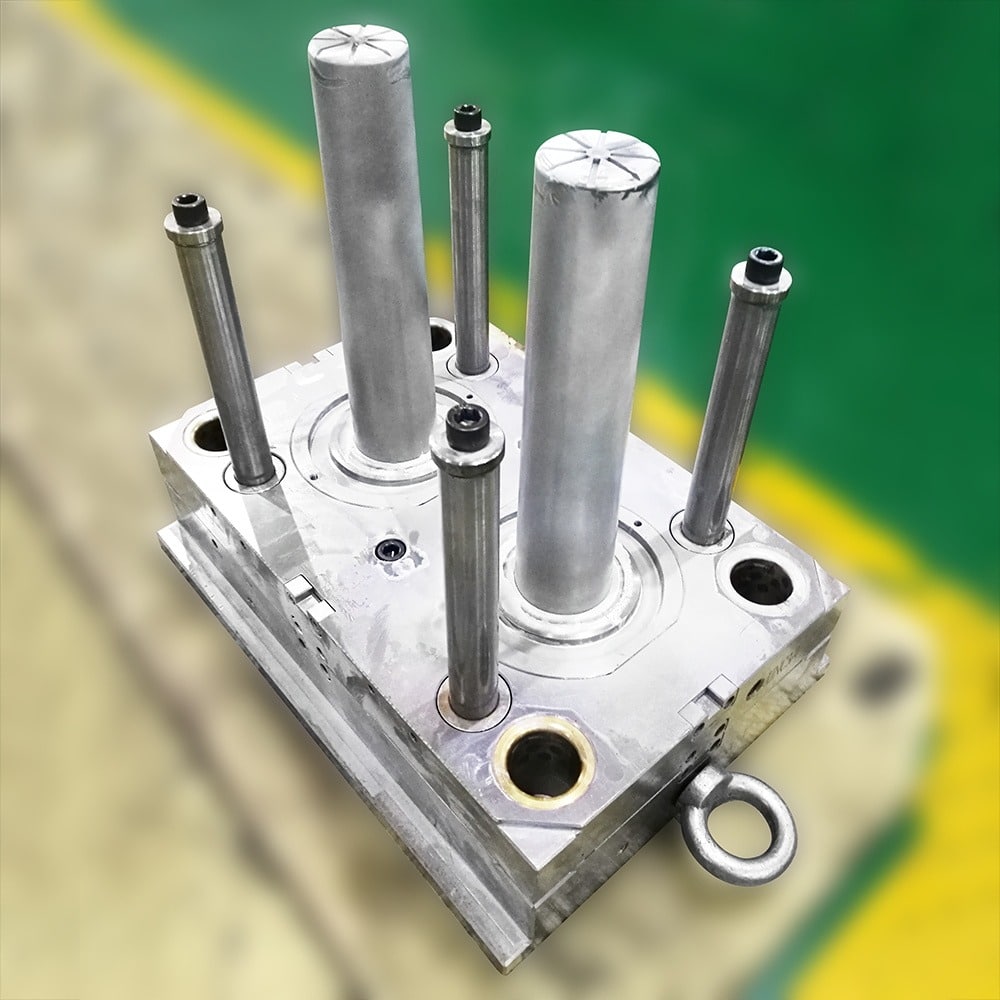

1: Guide rail and bearing

The guide rails and bearings at all shafts shall be kept clean and well lubricated. If the manipulator is operating in a dusty environment, the guide rail needs to be cleaned frequently. If you find any metal chips or powder, it may indicate poor lubrication. In order to ensure proper lubrication, it is critical to have an appropriate linear guidance system. Most manipulators have automatic lubrication systems and parts that need to be replaced regularly.

2: Manipulator cycle

One of the key points to keep the manipulator running well is to simply observe and listen, which can reveal a lot of information about the overall operation of the manipulator. The manipulator works through specific actions, so it listens to any abnormal sound, such as whistling, clicking, etc., which indicates that the bearing cannot rotate normally or that some other component is stuck.

The link part of the manipulator moves along the guide rail equipped with power cable and vacuum hose, and it will make a normal clicking sound, but the sound is smooth and stable. Check any bearings that can be observed to ensure that they rotate smoothly. Just check and listen to some signs of wear or need to be adjusted, which can greatly help to maintain the optimal operating state of the manipulator.

3: Drive system

If the manipulator is driven by the assembly frame transmission gear, pay attention to whether there is any hesitation or shaking during operation. All movements, except smooth and smooth movements, can indicate that the drive system is damaged or some foreign matters are stored inside. When the manipulator moves downward, the method to quickly check the action or backlash between the assembly beam and the transmission gear is to push and drag the moving arm, and feel abnormal movement (different back and forth movements).

However, due to the high tolerance accuracy of normal manufacturers, this test method will be very inaccurate. If you suspect that there may be a problem with the mounting beam and transmission gear, it is better to use a magnetic gauge holder with a long measuring range. After the backlash is adjusted according to the manufacturer’s instructions, check the full stroke of the shaft to ensure that there is no too tight place between the assembly beam and the transmission gear.

If the backlash cannot be adjusted, the mounting bracket and transmission gear may be worn and need to be replaced. If it is necessary to repair the assembly frame and transmission gear, it is better to replace both components at the same time to ensure long-term performance. As for the shaft driven by the conveyor belt, pay close attention to the debris falling from the worn conveyor belt and its damage. Check the pulley carefully, and pay attention to the signs of dust from the conveyor belt material.

Make sure that the belts and drive pulleys and sheaves are fully aligned. Belts that deviate in direction will wear out very quickly. As long as the system is driven by the conveyor belt, the preload of the conveyor belt can be checked according to the manufacturer’s instructions. These specifications will tell you the appropriate error in the specific position of the belt relative to the pulley.

4: Pneumatic system

Including multi axial servo drive, almost all manipulators will have pneumatic functions as long as there are wrist rotators and vacuum grabs. Pay close attention to the suction cup of the filter pressure regulating valve unit. If there is water in it, it indicates that the humidity of the compressed air source passing through the system is too high. A small amount of water and gas may be transmitted to the pneumatic valve and actuator, causing oxidation and internal pollution, which may eventually lead to sticking of the pressure regulating valve or intermittent sticking or failure of the actuator.

If the suction cup is equipped with an automatic dehumidification system, the contamination or discoloration on the suction cup also indicates that the moisture is increasing before removal. If water collects in the suction cup, it can enter the system even if the time is short, causing the above problems. If you notice any physical damage to the pneumatic hose, the system may leak.

If the pneumatic circuit is filled with air at normal operating pressure and there is a leak somewhere in the circuit, you should find a noticeable hissing sound more easily, which will help you determine the location of the leak.

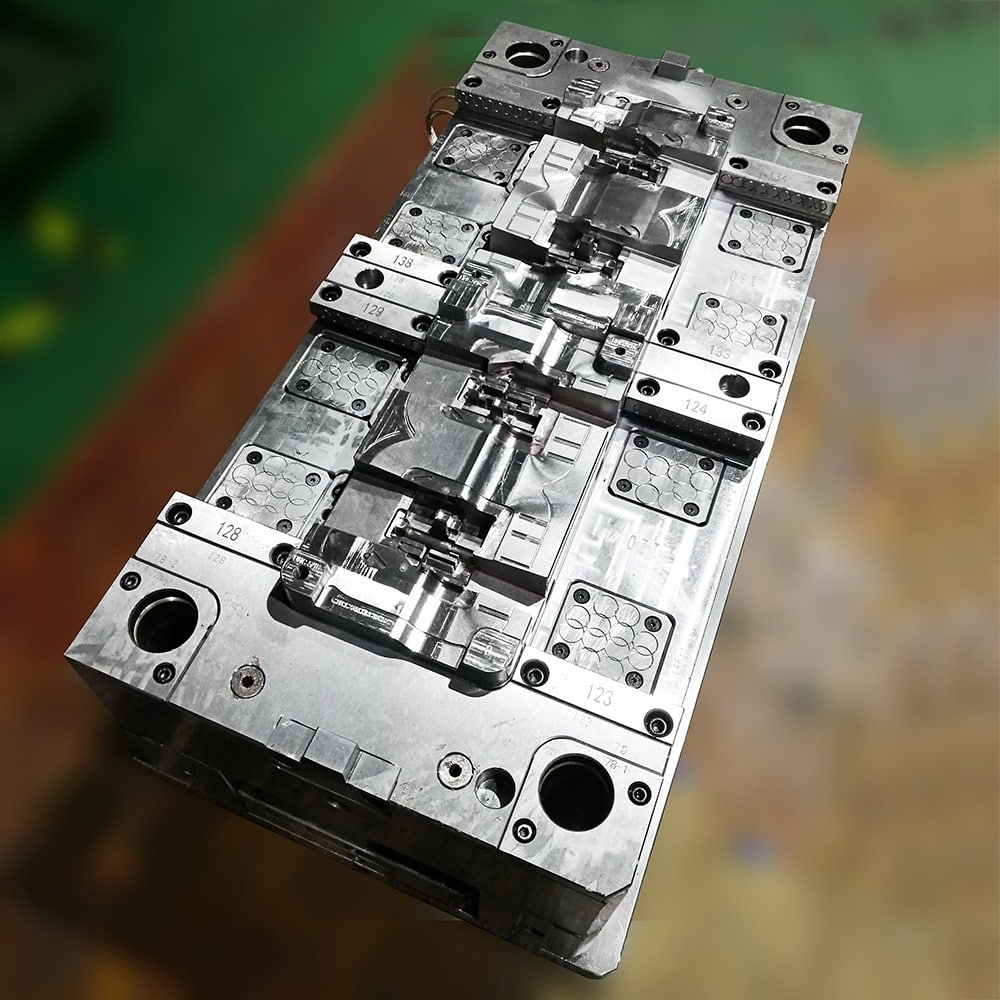

5: Check the forming equipment

The manipulator with standard configuration is usually installed on the template of forming equipment. When the equipment is running rapidly, the vibration from the forming equipment may be transferred to the manipulator and may cause damage. Simply observe the operation of the molding equipment, ensure that the mold movement is adjusted to a reasonable state, reduce the number of shaking or vibration, and can extend the life of the manipulator. In high-speed operation, the vibration frequency may be very high, and it is better to install the manipulator on a support structure independent of the forming equipment.

6: Pay attention to the wear of wiring

When checking the face of the mechanical watch, if black particles or powder are found, it indicates that the circuit wiring of the manipulator has signs of wear. However, even if you can’t find these wear signals, look carefully at all power supply, transformer or encoder cables, both inside and outside of the wiring path can also be used, because during the production cycle, the wiring of the manipulator or the wiring connected to the cable guide rail will eventually wear out and become invalid. Ensure the safety of wiring ties and reasonable installation of cables.

7: Check lubrication

The manipulator uses a spring loaded lubricating rod, which only needs to be replaced once a year unless there is evidence that the guide rail is not sufficiently lubricated. Equipped with automatic lubrication system, it can continuously lubricate along the movement of the manipulator. However, if there are some surfaces on which the manipulator cannot move normally, manual lubrication shall be carried out for these areas, or regular program control action of automatic system lubrication shall be carried out for lubrication.

If you find rust, corrosion or wear on any moving surface, or if it is just too dry, it means that they are not lubricated enough. Always refer to the manipulator manual for proper lubrication of metal parts. Assembly beam – Conventional gear systems are lubricated automatically by a lubricating oil storage unit, but need to be replaced annually.

8: Vacuum grab circuit

The vacuum should be formed nearly instantaneously, and the appropriate controller input should be equivalent to grasping products. If you find that the vacuum is turned on, then the input light source appears, and the delay time exceeds 2 seconds, it indicates that there is a vacuum pipeline leakage, defect or improper adjustment of the switching device. It can be easily tested through the external main control panel. If the manipulator is equipped with a digital vacuum switching unit, it can quickly and automatically fine tune the minimum threshold value of vacuum required for grasping products.