How to find an injection molding factory

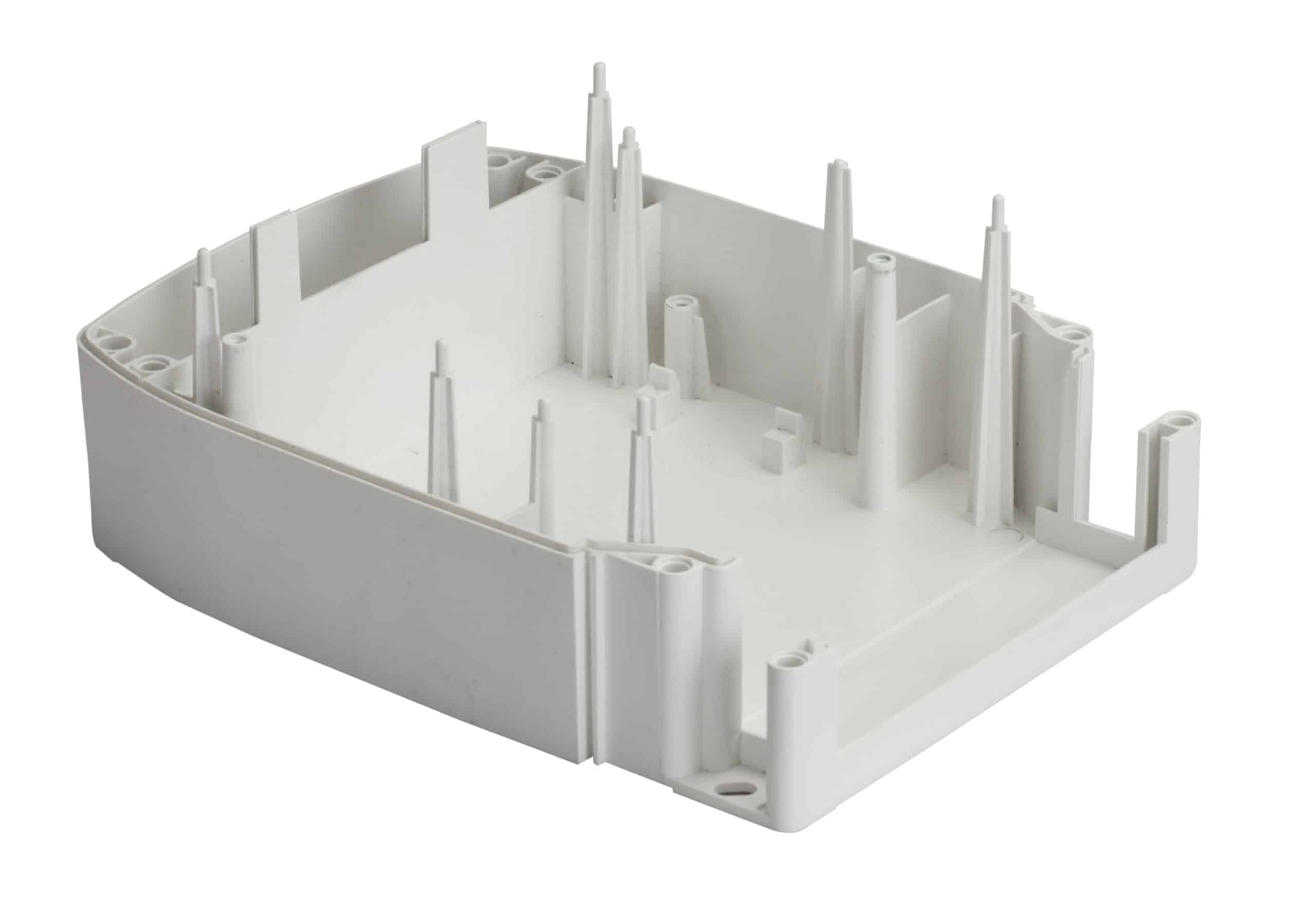

Clear PC Part For Household Appliances

In recent years, more and more people have started to enter the real industry with the help of new models such as the Internet and crowdfunding. Finding a reliable injection molding factory to put products into mass production has become the core. So, how should we choose a high-quality and reliable injection molding factory?

1、 Professional competence

First of all, we should conduct a 360 degree inspection of the injection molding processing factory to see whether it is a one-stop injection molding processing factory and whether it can provide one-stop services from mold design and manufacturing, product injection molding, plastic shell surface treatment (oil injection, silk screen, etc.).

2、 Quality test

Maybe what you have talked about is good, but you must carry out a small sample test. First, the injection molding factory provides proofing service according to the preset target requirements. Through this link, you can basically test the production quality of the injection molding factory. If the effect of the sample link is not very satisfactory, then the next big goods are basically worse. Therefore, proofing and testing is the last insurance mechanism, which must be carefully examined.

3、 Cost performance

The cost performance ratio is the last. Generally, small manufacturers negotiate prices with you. If you want to find a reliable injection molding processing plant, this link is usually the last. When you find an injection molding processing plant that meets the previous links, you usually find a two or so injection molding plants to compare their quotations. Through the final comparison of the region, price, service, etc., you can basically find the injection molding processing plant that best meets your needs.