Factors Affecting the Quality of Precision Injection Mold in the Manufacturing Process

Mold design, mold design will directly affect the quality of plastic products. Because the mold cavity size is obtained from the required size of plastic products plus the shrinkage of the materials used, and the shrinkage is often a value within the range recommended by the plastic manufacturer or engineering plastics manual, it is not only related to the mold gate form, gate location and distribution, but also related to the crystal orientation (anisotropy) of engineering plastics, the shape of plastic products, the distance and location from the size to the gate.

The main factors affecting plastic shrinkage include heat shrinkage, phase change shrinkage, orientation shrinkage, compression shrinkage and elastic recovery.

These influencing factors are related to the molding conditions or operating conditions of precision injection molding products. Therefore, the mold designer must have rich experience in design and injection molding, and must consider the relationship between these influencing factors and injection molding conditions and their apparent factors, such as injection pressure and cavity pressure and filling speed, injection melt temperature and mold temperature, mold structure and gate form and distribution, as well as gate sectional area, product wall thickness, content of reinforcing filler in plastic materials The crystallinity and orientation of plastic materials.

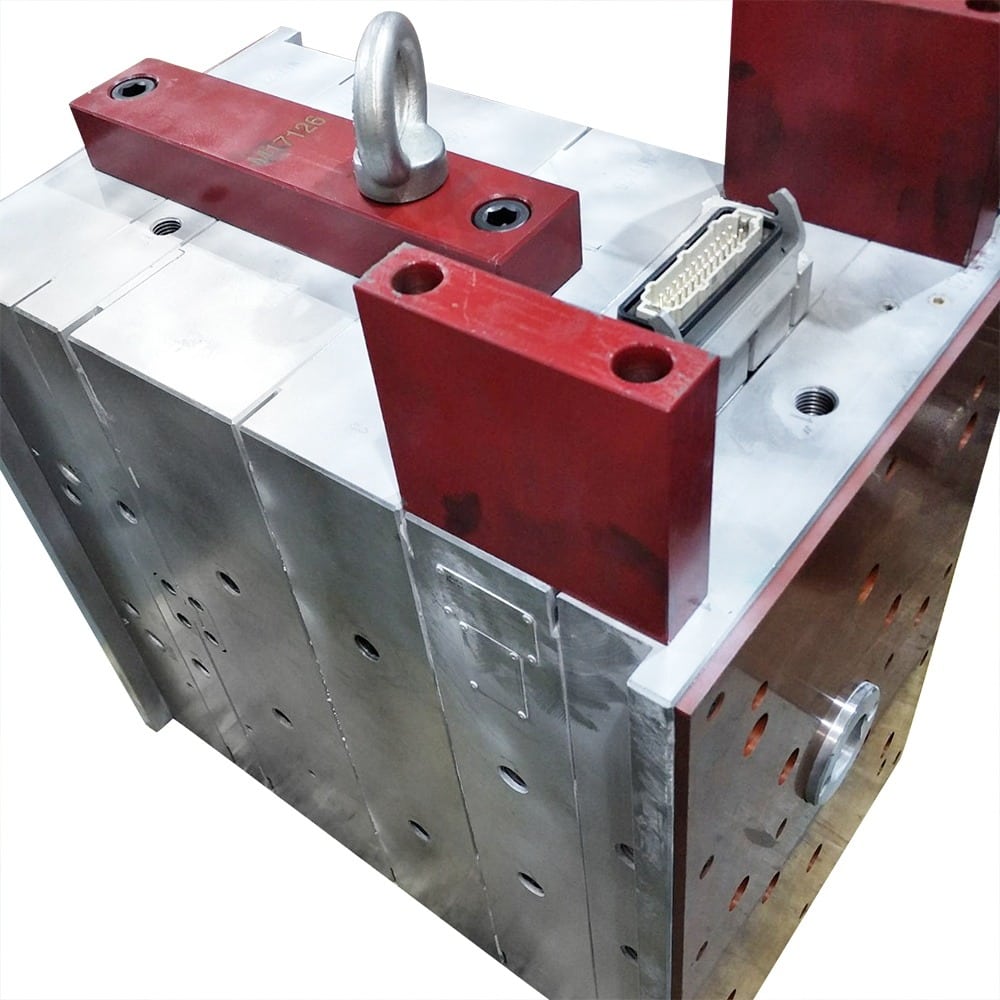

The advantages of precision injection mold manufacturing in injection molding are fast production speed, high efficiency, automatic operation, multiple designs and colors, shapes from simple to complex, sizes from large to small, and accurate size. The products are easy to be updated, and complex shapes can be formed. Injection molding is applicable to mass production, products with complex shapes and other molding processing fields.

There are many kinds of plastic raw materials used in the processing process, and the types and forms of mold design are also varied. In addition, the familiarity and operating skills of employees with specific injection molding machines. The process of precision injection molding involves mold design, mold manufacturing, raw material characteristics and raw material pretreatment methods, molding process, injection molding machine operation and other factors, as well as processing environmental conditions, Complex processing flow closely related to product cooling time and post-treatment process.