Hot runner application main technology key

A successful hot runner mold application project requires several components to be guaranteed. Among them, there are two most important technical factors: one is the control of plastic temperature, and the other is the control of plastic flow.

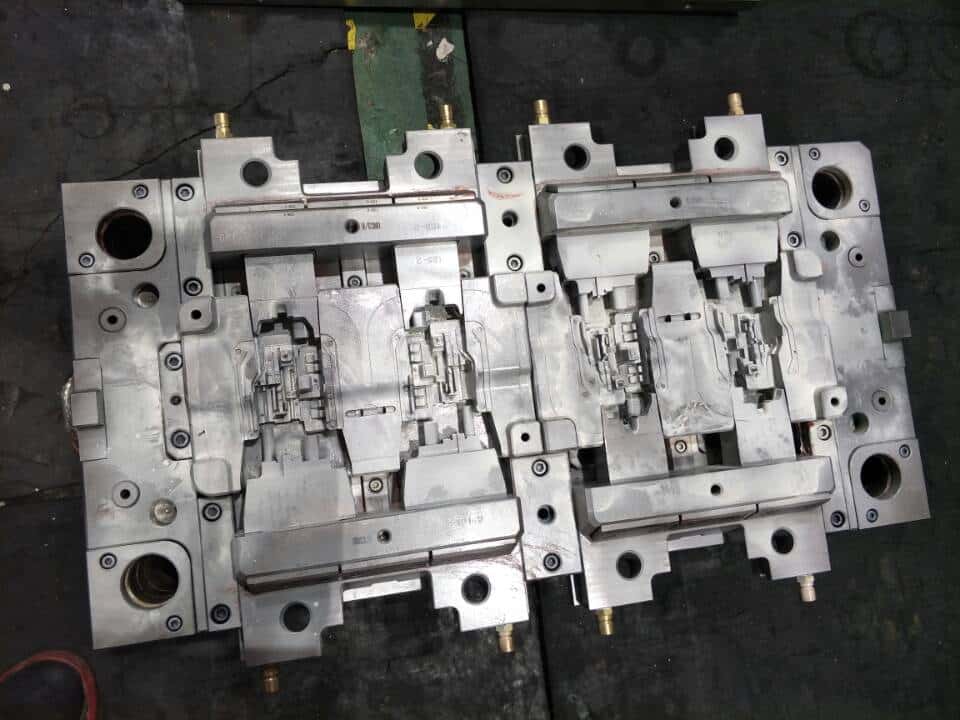

plastic injection mold

1, the control of plastic temperature in the hot runner mold application of plastic temperature control is extremely important.

Many production process and product quality problems arise directly from the hot runner system temperature control is not good. Such as the use of hot needle gate method injection molding when the product gate quality is poor, valve gate method molding valve pin closure difficulties, multi-cavity mold parts filling time and quality inconsistent problems. If possible, you should try to choose a hot runner system with multiple regions to control the temperature separately, in order to increase the flexibility and adaptability.

2, the plastic flow control

Plastic in the hot runner system to flow balance. The gate should be opened at the same time so that the plastic synchronously fill the cavities. For parts with significant differences in weight to balance the sprue size design. Otherwise, there will be some parts not enough mold pressure, but some parts are overfilled and over-pressurized, poor quality and other problems. Hot runner sprue size design should be reasonable. Size is too small mold filling pressure loss is too large. Size is too large, the hot runner volume is too large, plastic in the hot runner system for too long, damage to the material properties and lead to parts can not meet the requirements of use after molding.

The hot runner pouring system can be understood as an extension of the injection molding machine. The function of the hot runner system is to adiabatically deliver the thermoplastic melt near the molding mold or directly into the mold.

The hot runner can be heated independently and thermally insulated in the injection mold, thus compensating separately for the heat loss due to contact with the “cold” mold. Hot runner molds have been successfully used to process a wide variety of plastic materials, and almost any plastic material that can be processed with a cold runner mold can be processed with a hot runner mold.