How Many Types Of Lathes Are There?

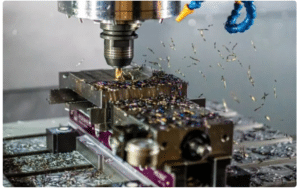

The lathe is the master machine of all equipment, as is the case for plastic mold factories, so the understanding and classification of lathes is the most basic. First of all, let’s know what a lathe is. A lathe is a machine tool that mainly uses turning tools to turn rotating workpieces. On the lathe, drills, reamers, taps, dies and knurling tools can also be used for corresponding processing. Lathes are mainly divided into nine