What should be paid attention to when selecting the mold surface in mold design?

Mold parting surface

Mold terminology. Generally speaking, a mold is composed of two parts: movable mold and fixed mold (or male mold and female mold). The parting surface refers to the part that can be contacted when the two parts are in a closed state, and it is also the parting surface that divides the workpiece or mold part into specific blocks of the mold, which has a broader meaning.

The design of parting surface directly affects the product quality, mold structure and the difficulty of operation, and is one of the key factors for the success of mold design.

The points to be noted when selecting the parting surface are as follows:

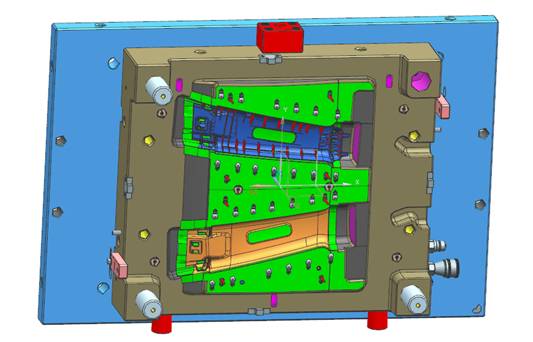

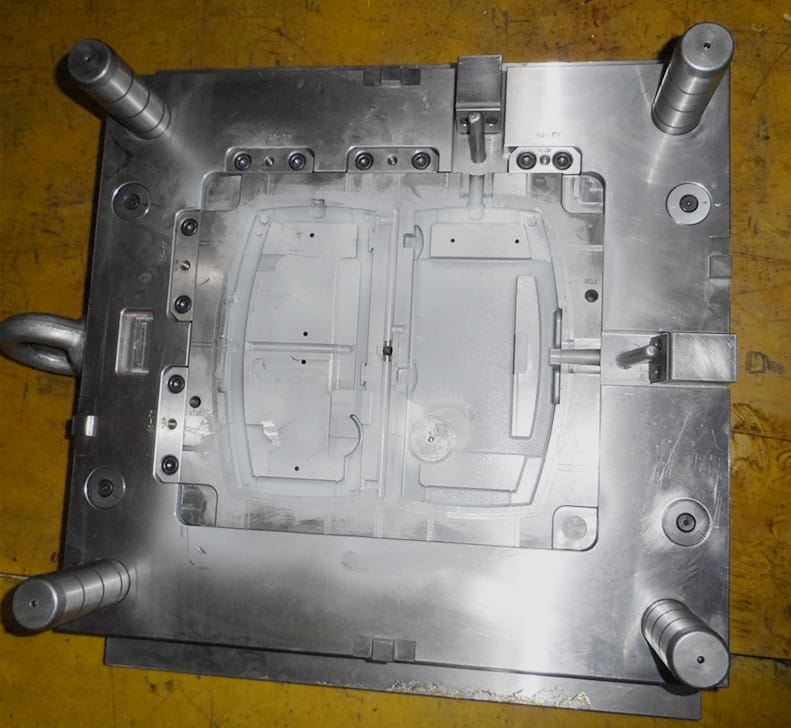

Iphone Plastic Housing Mould

1. It should be selected at the maximum section of the injection molded part contour dimension to facilitate the smooth removal of the injection molded part from the cavity.

2. The surface quality and appearance requirements of injection molded parts as well as the accuracy of size and shape shall be guaranteed.

3. The parting surface shall be designed to facilitate exhaust and prevent overflow.

4. The purpose of parting surface design should be to facilitate mold processing and simplify its structure.

The selection of parting surface of plastic mold not only relates to the normal molding and demoulding of plastic parts, but also affects the mold structure and manufacturing cost to a certain extent. To sum up, the overall selection principle of parting surface is to ensure the quality of plastic parts, facilitate product demoulding, simplify the mold structure, meet customer needs, design satisfactory molds for customers, manufacture high-quality molds, and produce high-quality products.