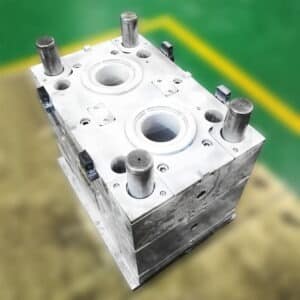

How to Improve the Precision of Plastic Mold

How to Improve the Precision of Plastic Mold For the injection mold, the precision of plastic parts is grade 3 and 3a, the weight is 5g, the hardened gating system is used, and the number of cavities is 4-6; The plastic parts are of general accuracy (4-5 levels), the molding materials are locally crystalline materials, and the number of cavities can be 16-20; The weight of plastic parts is 12-16g, and the number of cavities