Plastic Injection Molded Parts Surface Uv Treatment Of Attention

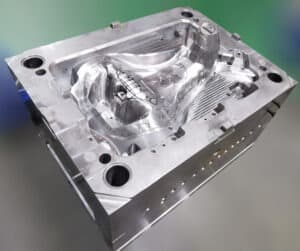

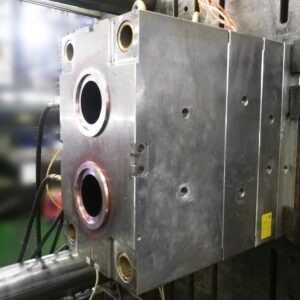

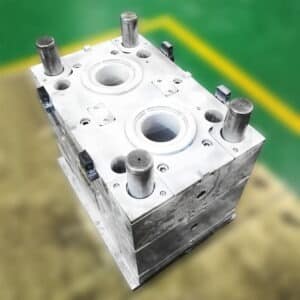

Plastic injection molded parts surface UV treatment of attention After UV treatment, the surface of plastic injection molded parts can be brighter and not easy to be scratched. The main process is to spray a layer of transparent oil on the surface, which needs to be dried by UV light: Plastic injection mold manufacturing 1. Due to the UV paint curing speed, high production efficiency, through the UV curing, 30 minutes can; 2. Excellent coating