Three mechanical states of plastics

In nature, we divide all substances into three states of aggregation at room temperature: liquid, gas and solid.

Polymers represented by amorphous linear polymers, due to the continuity of molecular structure and their huge molecular weight, their aggregation state is different from that of ordinary low molecular compounds, but under different thermal conditions, they exist in three unique forms, namely, glass state, high elastic state, and viscous flow state

There is no gaseous polymer. Before being heated and possibly gasified, the molecular structure of the polymer has been completely destroyed, becoming a low molecular gasified substance or carbide

The glassy state of polymer is actually a form of solid state, which is characterized by the common properties of solid materials within a certain temperature range, and is similar to ordinary glass in some mechanical properties.

Viscous flow state of polymer is a unique liquid. Within a certain temperature range, it has mechanical properties that can flow and are different from ordinary low molecular liquid.

The high elastic state of a polymer is a unique form in the temperature range between the glassy state and the viscous fluid state.

Like other substances, macromolecular polymers have a relatively stable form under specific temperature and pressure. For example, under ordinary conditions of use, plexiglass can be regarded as the representative of glass state and liquid resin as the representative of viscous flow state.

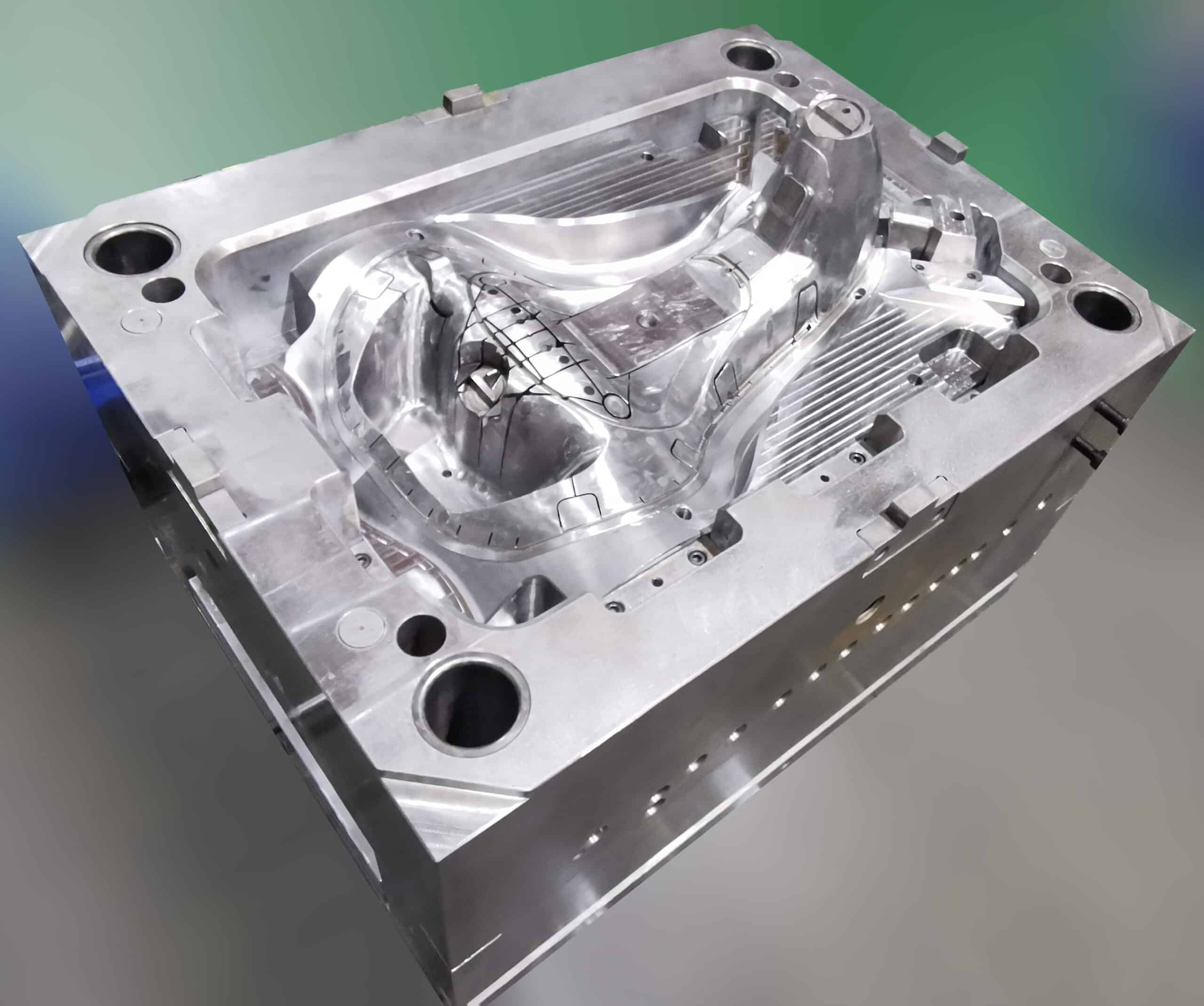

Unscrewing Plastic Injection Mold

(1) Glassy state

The movement of the plastic molecular chain segment in the glassy state is basically at a standstill. The molecules vibrate at their own positions, and the molecular chains are wound into clusters or curls, interlaced and disordered;

When subjected to an external force, the molecular chain segment will make a small expansion and change of bond angle in a short time. The whole plastic body has a certain rigidity and strength. In this form, plastic parts can be used or machined

Generally, the glass transition temperature of non crystalline plastics is higher than room temperature. We can regard the plastic raw material particles and shaped parts as glass.

(2) Hyperelastic state

The kinetic energy of plastic molecules in the high elastic state increases, and the chain segments expand into a network, but the movement of the molecules is still maintained in the option of small chain segments. The position between chains does not move, and they can change slowly under the action of external forces. When the external forces are removed, the plastic slowly returns to its original state. In this state, the plastic has a kind of elasticity similar to rubber, so it is also called rubber state, usually called elastic or rubber polymer, It is a high elastic polymer at room temperature,

The high elastic state has two characteristics

a. Large deformation can be produced under small force, and the original state can be restored after contact with external force

b. The high elastic deformation does not occur instantaneously, but develops gradually over time. Unlike ordinary elastic deformation, the deformation can be completed after a period of time under the same external force, and the deformation is up to, and the relaxation is also obvious – in fact, the high elastic state of plastic only occurs during thermal processing

(3) Viscous flow regime

Plastic molecules in the viscous flow state have disintegrated network structure. Macromolecular chains and segments can move freely. This is the form of plastic liquid. However, the viscosity is large, the physical composition is different, and the mechanical properties are different. When external forces are given, the molecules are easy to slide each other, causing deformation of the plastic body. When external forces are removed, the plastic body will not return to its original state.

The process of plastic thermoforming can be described as follows: through the action of heat and force, the plastic can be transferred from the glassy state at room temperature to the viscous flow state through the high elastic state, and then injected into a closed mold cavity with a certain shape, and then gradually cooled in the mold cavity, and then transferred from the viscous flow state to the glassy state, finally forming products with the same shape as the mold cavity.

Plastics can only be injected, filled and molded in the viscous flow state, that is, the processing temperature range of plastics can only be from the viscous flow temperature (or the melting point of crystalline plastics) to the decomposition temperature. If the range is wide, processing will be easier. If the range is narrow, the processing temperature limit is large, and processing will be more difficult. The former is represented by polyethylene, and the latter is represented by polyvinyl chloride, Frequently used ABS also belongs to this wide range.