What Is A Plastic Over Moulding?

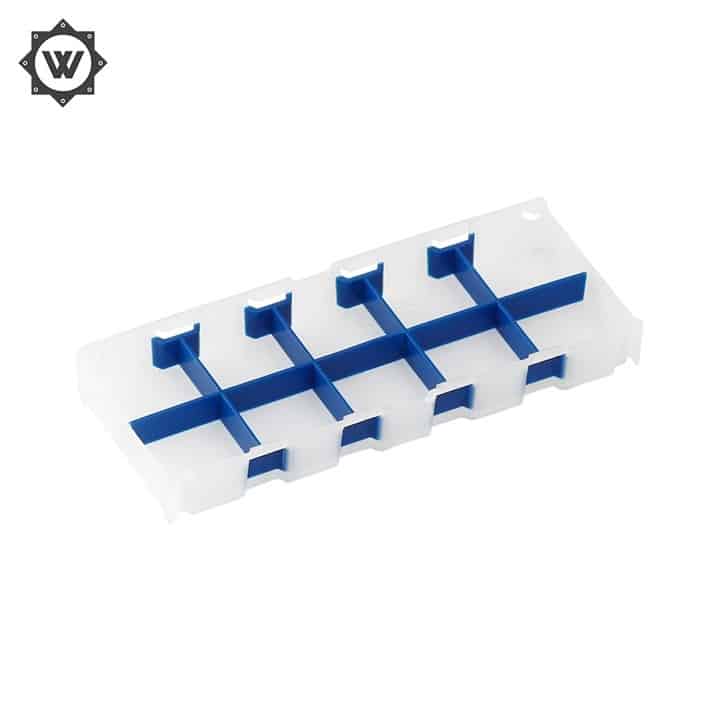

The main body consists of two parts, one refers to the plastic inside and the other refers to the rubber outside. The method of overmolding, hard plastic part, is the same as that of conventional plastic mold design. For the soft rubber part, the hard plastic part is molded first, and then manually put into the plastic injection, so there is no need to apply shrink rate for the second mold during mold design.

After the first plastic part cools down, it is put into another mold for injection molding again. The plastic overmold is generally used on the handle.

Among them, the plastic particles such as artificial rubber, TPU and TPR are common on the outside, while ABS, PC and PP can be used on the inside.

The defects of the plastic over mold are not suitable for injection molding of high-precision dual raw materials and multi raw materials injection products; The forming production cycle time is relatively long, and the production efficiency is also lower than the two-color mold. However, the advantage of the plastic overmold is that it can be formed, produced and processed by ordinary injection molding machines, and the investment in machinery and equipment is relatively small.

The over mold not only has good advantages, but also has bad defects. In fact, we should make decisions according to customer requirements and product structure.