What are the basic characteristics of auto plastic mold processing?

(1) The processing accuracy of plastic mold is high. A mold is generally composed of concave die, punch die and die frame, and some may be multi-piece integrated module. Therefore, the combination of upper and lower die, the combination of insert and cavity, and the combination between modules all require high machining precision. The dimensional accuracy of precision mold is often up to μm class.

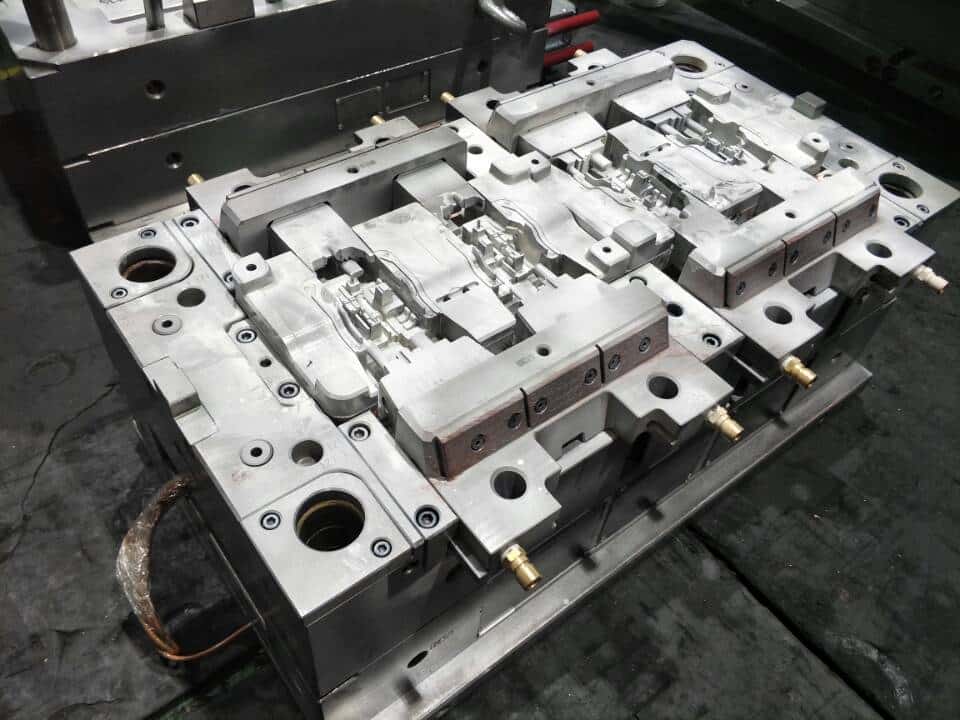

(2) Complex shape and surface. Some products such as automobile covering parts, aircraft parts, toys, household appliances, the shape of the surface is composed of a variety of curved surfaces, so the mold cavity surface is very complex. Some surfaces must be treated mathematically.

auto parts

(3) small batch. Mold production is not mass production, in many cases often only produce one pay.

(4) many processes. Milling, boring, drilling, reaming and tapping are always used in die processing.

(5) Repetitive production. The use of molds has a life span. When the use of a mold exceeds its life, it is necessary to replace a new mold, so the production of molds is often repetitive.

(6) copying processing. Sometimes there is no drawing or data in mold production, and copying processing should be carried out according to the real thing. This requires high precision imitation, no deformation.

(7) Excellent mold material, high hardness. The main materials of the mold are made of high quality alloy steel, especially the molds with high life, which are often made of Leytenite steel such as Crl2 and CrWMn. This kind of steel from blank forging, processing to heat treatment are strict requirements. Therefore, the preparation of processing technology can not be ignored, heat treatment deformation is also a serious problem in processing.

According to the above characteristics, in the selection of machine tools to meet the processing requirements as far as possible. For example, the function of numerical control system is stronger, the machine tool precision should be high, the rigidity should be better, the thermal stability should be better, and the function of copying should be better.