What parameters should be paid attention to when designing injection mold

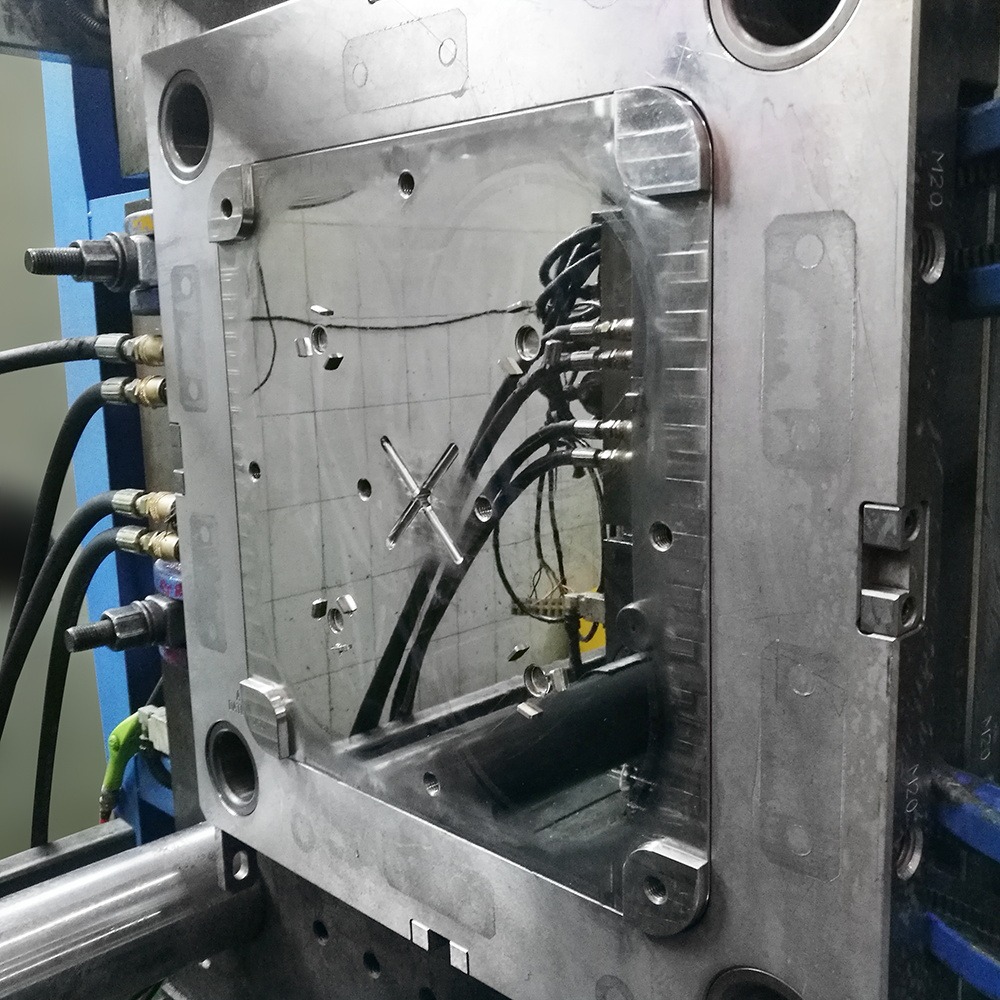

There are two templates on the injection molding machine, one of which is incomprehensible, which is called fixed template; The other one can be moved, which is called movable template. The mould is fixed on the two formworks by screws and pressing plates respectively. When the mold is opened, the moving template of the injection molding machine moves to open the mold.

After the mold manufacturing is completed, the injection molding shall be carried out, the injection molding machine shall be installed, and the products shall be started to be produced. However, there are many types of injection molding machines, and each type of injection molding machine has its own parameters. The mold design must be able to meet the model requirements of the injection molding machine provided by the customer, otherwise it will be unable to produce.

There are many design parameters of the injection molding machine. Here we will focus on several parameters related to the mold. We hope that readers will pay attention to the specific design of the mold.

1. Injection volume

The injection volume is the maximum mass (or volume) of the injection molding machine that can eject the melt at one time during production, representing the maximum injection capacity of this type of injection molding machine. The amount of glue used in the designed the first mock examination is less than the injection amount of the injection molding machine. Otherwise, the product cannot be produced due to dissatisfaction.

2. Clamping force

It is the pressing force of the injection molding machine on the template when the mold is closed. The clamping force required by the molded product during molding must be less than the rated clamping force of the selected injection molding machine. Otherwise, the melt adhesive is easy to run away from the parting surface, resulting in flash.

3. Tie rod spacing

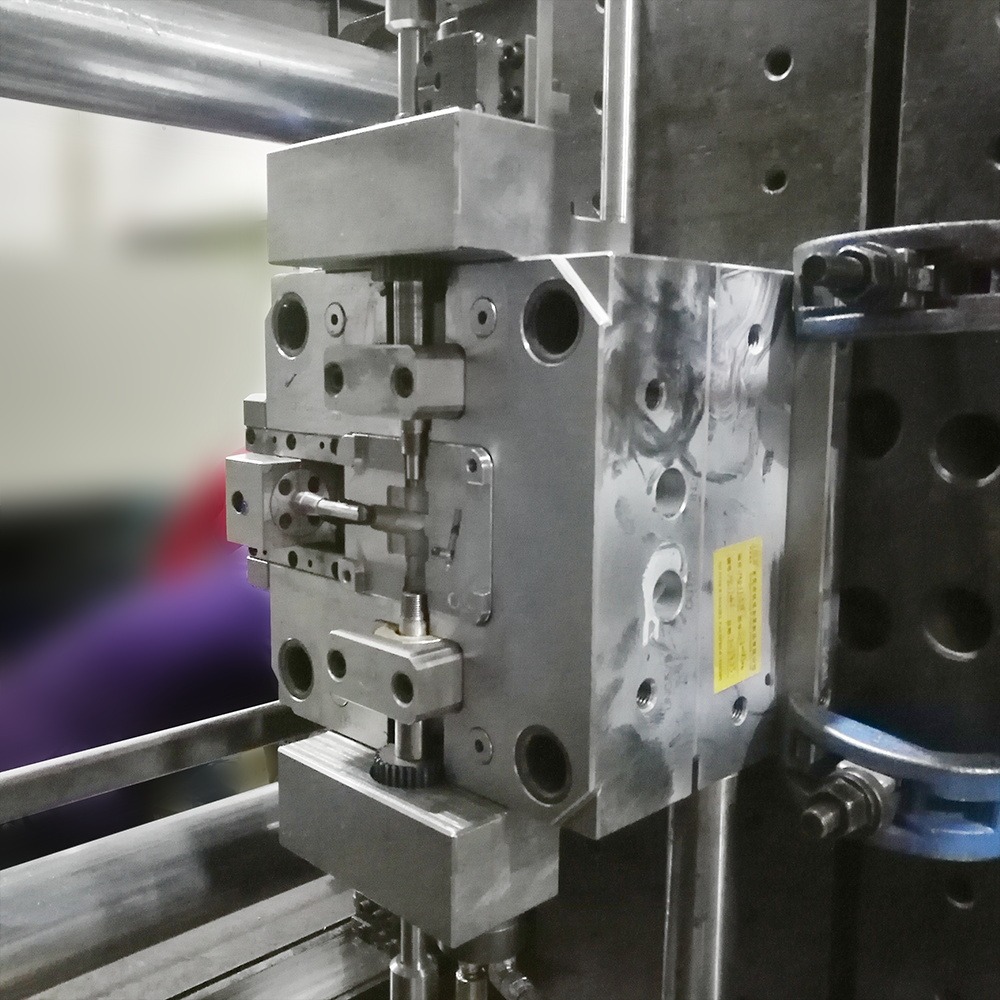

There are four tie rods in the dead corner of the fixed template and movable template of the injection molding machine. Their role is to ensure that the injection molding machine has sufficient strength and stiffness, and they are also responsible for sliding the template. However, it often limits the overall dimension of the mold, because the mold is lifted in from the middle of the pull rod during installation.

The overall dimension of the mold shall not be greater than their corresponding pull rod spacing at the same time. If one of the length dimensions of the mold exceeds the pull rod spacing, check whether the mold is lifted into the pull rod workshop by rotating. If the rotating lifting cannot be carried out, only the mold size can be changed or the injection molding machine can be replaced.

4. Nozzle size check

The nozzle head of the injection molding machine is generally spherical. When selecting the sprue sleeve, the spherical radius of the sprue sleeve should be equal to the spherical radius of the nozzle. In order to prevent the high-pressure melt from overflowing from the contact gap between the nozzle and the sprue sleeve, the ball radius of the sprue sleeve should be generally larger than that of the nozzle. At the same time, the size of the small end of the main runner should be slightly larger than that of the nozzle hole, so that the nozzle and the sprue sleeve can be aligned easily.