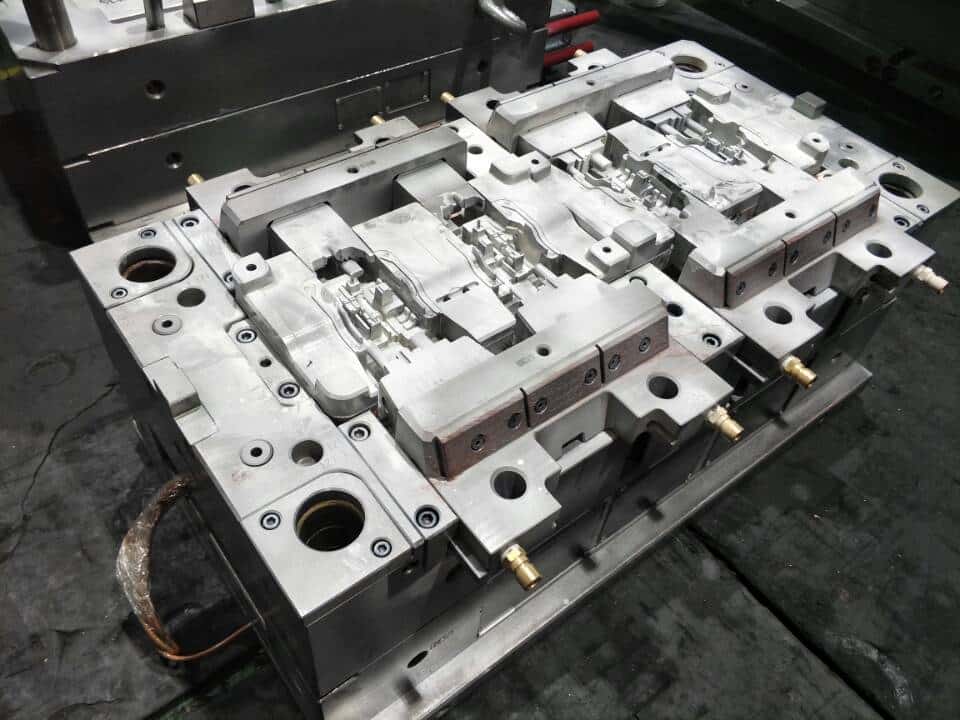

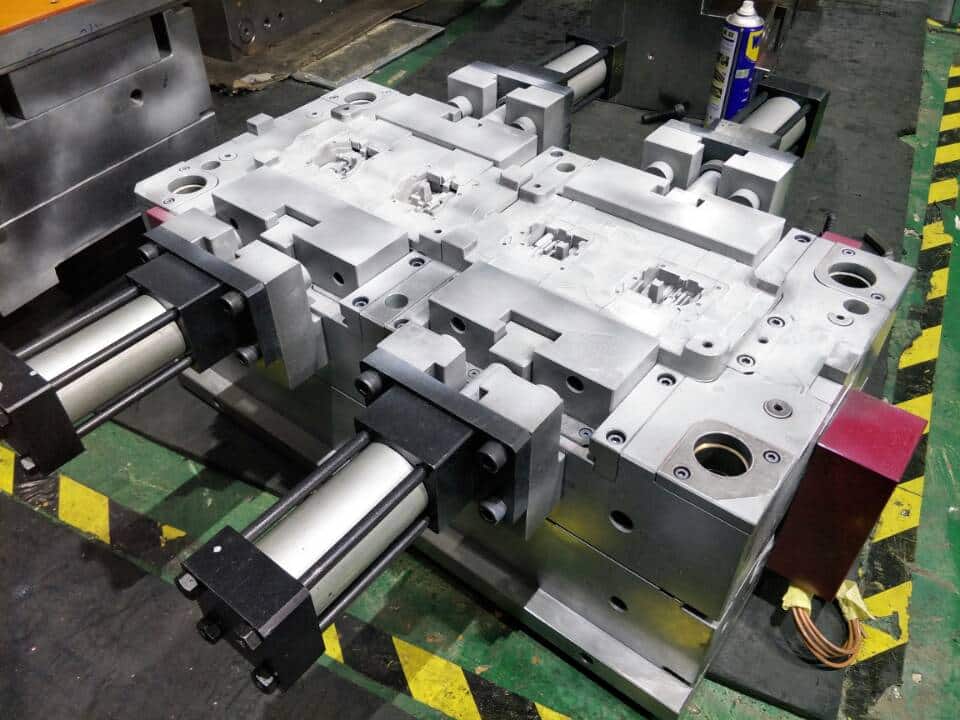

Basic composition and structure of injection mold

1. Gating system: the channel for molten materials to flow into the mold cavity from the injector nozzle, including the main runner, splitter, gate, cold feed well, pulling rod, etc.

2. Molding parts: parts for molding plastic parts, such as core, cavity and other auxiliary parts.

3. Temperature control system: used to adjust the temperature of the mold.

4. Plastic part ejection system: including side parting mechanism, secondary ejection mechanism, first reset mechanism and several sequential distance parting mechanisms.

5. Installation part: the part where the mold body is reliably installed on the injection machine.

6. Connection system: the connection system that integrates all structural members.

7. Guide system: ensure the moving accuracy of each structural member, such as guide post, guide chute, etc.