What are the factors that affect the quality of injection mold?

Injection mold manufacturing is a very complex process. From injection mold design, processing, assembly, mold testing to mass production, any point in the whole process may affect the quality of injection mold. So what are the factors that affect the quality of injection mold?

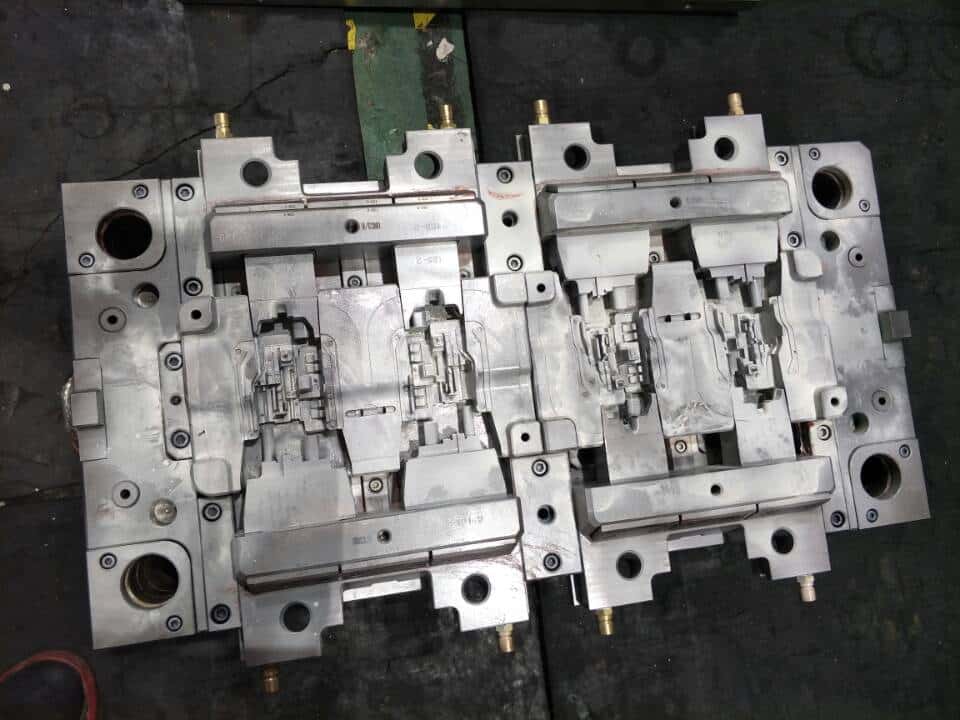

plastic injection mold

1、 Selection of die steel

The choice of steel is the decisive factor for mold quality. The first task is to select reasonable steel.

The criteria for steel selection are:

1. According to the requirements of injection molding materials: different plastics should use different steels, such as requirements for good polishing performance and corrosion resistance. 2. Steel price: considering the cost of injection mold, mold steel should use materials corresponding to the mold life to avoid unnecessary waste in plastic injection molding. 3. Surface treatment requirements: the surface treatment of the mold is also very important. Nitriding can improve the surface hardness of steel and effectively prolong the service life of die. Electroplating can effectively change the properties of die steel. For some high brightness and corrosion resistant plastic parts, electroplating can be used to enhance and improve the performance of steel.

2、 Reasonable design of injection mold structure

The mature mold structure should not only consider the material performance, shrinkage, molding temperature, elastic tensile deformation coefficient of the product, but also consider the cooling water path, speed of opening and closing the mold, etc. The reasonable injection mold structure can effectively extend the mold life, ensure the smooth production of the mold, improve efficiency and reduce costs.

3、 Injection mold processing

The reasonable mold processing technology layout can speed up the mold production cycle, shorten the processing time, and effectively save costs. More importantly, accurate and reasonable processing can ensure the stability of the mold in the production process and extend the life of the mold. In addition, poor processing may affect the mold movement, shorten the mold life, and cause the mold to crack or even break in the production process.

4、 Selection of standard parts

Although standard parts are not directly involved in molding, they control the operation of the entire mold. Good standard parts shall be wear-resistant, hard, high precision and not easy to deform.

5、 Injection mold flying mold

The mold flying process depends on the experience of the mold fitter. It seems very simple, but it is a technical work. This is a major part of a complex mold.

6、 Polishing/Texturing

The polishing of injection mold is the last step of mold manufacturing. The polishing is directly reflected on the plastic parts, so this is a very important work. Polishing also helps mold movement, especially for demoulding. Generally, some molds cannot be produced smoothly because of poor polishing, high resistance and difficulty in demoulding.

7、 Injection mold assembly

Mold assembly is like assembling a machine. Each component and each screw must be free from errors. Otherwise, the consequences will be very serious. It will lead to product defects, affecting production, and the worst is to damage the mold and lead to scrap. Therefore, assembly work must be carried out very carefully. In the process of assembly, pay special attention to the cleaning of molds such as waterways and screw holes.

8、 Cooling water circuit

Anyone who has experience in injection molding knows how important cooling is to injection molding. Due to the increase of price and labor wage, the profit brought by one second reduction in each injection cycle is very relevant. However, when the production cycle accelerates, the temperature of the injection mold will rise. Without effective control, the mold will be too hot to form. It may even lead to die deformation or scrap. Therefore, excellent waterway design is particularly important, including layout density, diameter and connection between waterways.

9、 Injection Mold Maintenance

The maintenance of injection mold mainly refers to the maintenance during mold production. After each use of the mold, full maintenance shall be carried out, especially the rust prevention of the molded parts and the main moving parts.