How to choose a suitable and powerful manufacturer from thousands of injection molding manufacturers? I think the following points should be paid attention to:

- Price is not unique. Quality, cycle and service are also important

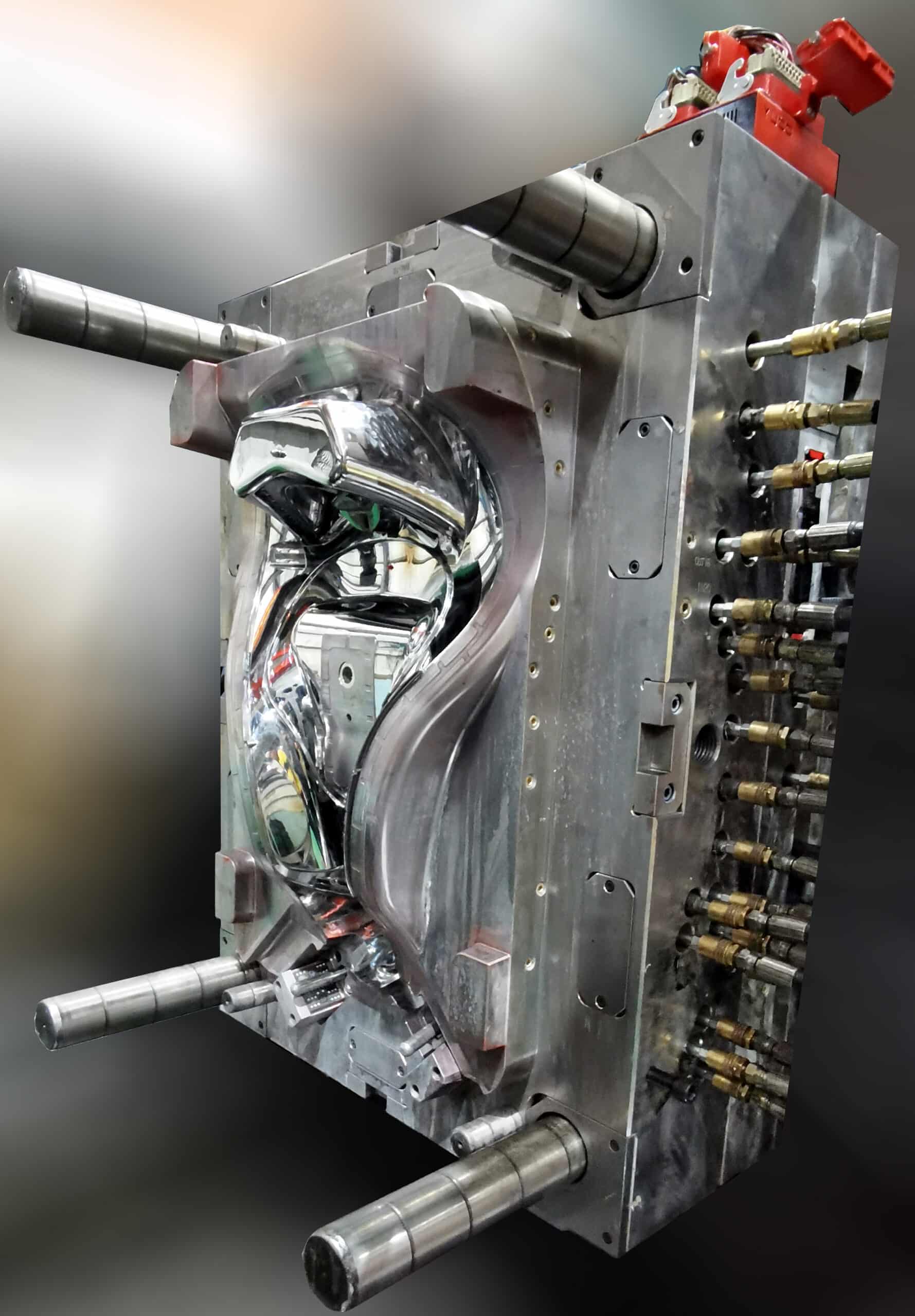

There are many types of injection molds. Generally, injection molding manufacturers will choose different processing technologies according to the material, physical and chemical properties, service life, dimensional accuracy requirements, and other factors.

Due to the differences of the parts, more advanced processes such as hot runner or gas assisted forming nitrogen cylinder are required in mold design. As a mature injection mold manufacturer, it should have spark machines, computer gongs, wire cutting machines, various high-precision grinders, advanced three coordinate detectors, computer design and related software.

Injection mold processing and production

- Product design and mold manufacturing are equally important

When developing a new product, some product developers only pay attention to the research and development of the product, and tend to neglect the communication with the injection mold manufacturing after the later mold opening, whether the product structure can be realized in the mold manufacturing, the risks in the processing process, etc. In fact, after the preliminary confirmation of the product design scheme, they communicate with the injection mold processing manufacturer in advance, This can ensure that the later product modification will not be made because the parts are difficult to process, which will also affect the production cycle of the mold.

- One stop mold service providers can communicate more quickly and effectively

After the mold is completed and the mold test is also very smooth, if no qualified injection molding manufacturer is found, it will also cause some difficulties for the later batch production. Because this is mainly related to the processing airport and process of parts and the technical experience of operators. With a good mold, you also need to have a good molding process. It is better to choose a one-stop cooperation. Mingyang Yutong can provide you with one-stop service of mold design, manufacturing and injection molding, so as to avoid multiple communication and save communication costs.

There are a variety of processing plants, both good and bad. When purchasing such parts, how to identify reliable mold manufacturers can be seen and identified from a technical perspective.

1、 Look at the scale of suppliers

It is easy to form an extreme misunderstanding about scale. Don’t be greedy for large-scale businesses. Although large-scale businesses have perfect equipment and management, others have corresponding customer markets, and the corresponding parts produced are more specialized. It is difficult to squeeze in now, and they may not meet the requirements. There is no large order in the future, which easily leads to the interruption of cooperation or the other party’s non cooperation, even if the cooperation continues, The delivery time is also decided by the other party, which will cause you delay and loss.

The other is the small scale, or even the intermediary, who will hire and contract for his own work. We should also consider carefully. It is difficult to guarantee the quality and delivery time, even a scam, or run away after receiving a large order.

Therefore, the scale of the partner is similar to that of your company, and the price of the mold you open is attractive to him, which can establish a stable cooperative relationship; Or your company’s industry is exactly what they want to get involved in; Just like you are in the auto industry, a manufacturer that has never produced auto parts molds has a little interest in you.

2、 Supplier’s production capacity and quality control capability

The principle is the same, that is, scale matching. The number of precision parts you need to process will match the capacity of the supplier. For example:

If the precision of your mold is required to be less than 0.01mm, the mold supplier should use slow wire cutting or electric spark, or even in the constant temperature workshop to meet the requirements, and there should be a certain precision of CMM tools inspection to ensure the delivery of the mold.

When the contract is not signed, you must check and confirm in person. If the supplier says that some equipment does not exist and needs to be manufactured elsewhere, the secondary supplier should also go to investigate.

If possible, ask the suppliers about the products they have made before, the customers they have cooperated with, the effect, the accuracy, whether they have made the same products, etc. Finally, we must check the authenticity of the implementation.

3、 Check the supplier’s production scheduling plan and quotation

It is determined to cooperate. Before signing the contract, the supplier is required to list the time cycle and time nodes of product processing in detail, just like how much time is needed for technical exchange and what needs to be done. And some details, such as blanking, rough machining, finishing, heat treatment, fine grinding, etc. Whether each process can be carried out after the completion of the previous process, or how long it needs to be adjusted (such as heat treatment, if the arrangement is not good, and the processing is completed but there is no furnace, the time will be wasted);

It is also important to understand the risk of delivery time. After the above suppliers are listed for you, you should also judge the reliability of their list according to their experience or by referring to others’ experience. The most direct and simple way is to shop around three suppliers, see how different several suppliers say, and then check with each other.

The same is also true of quotation. In terms of quotation, it depends on the supplier’s cooperation attitude (sincere cooperation or fraud) and cost control ability. In addition, it depends on the supplier’s proficiency in the industry, whether the expenses quoted are complete, and whether the price is objective.

The common way is to make the price of the other party’s series products, just like how much a set of equipment costs, how much a set of molds costs, raw materials, machining, heat treatment, design and development, management costs, and how much profit the supplier wants to leave. If possible, it is clear that the selected supplier can cooperate with the best. The advantages are that you can see clearly. 1, no one will suffer losses, win-win,; 2. Check whether the supplier’s cycle plan is reliable from the side.

In terms of quotation, don’t try to be too cheap to drive down the supplier’s profits. If you pay enough, the quality and speed of the other party will be given to you. Cooperation is two-way.

4、 See the supplier’s project control ability

In the process of production, we must not relax, especially when the mold is very important, we must investigate the specific situation and implementation according to the project cycle and time point reported to you before. If there is any abnormality, we will immediately analyze, discuss and deal with it, and make your remedial measures.

The penalty for failure to complete the contract is not necessarily the most effective. The best way to control the project is to find, solve and prevent the next risk in a timely manner, rather than focusing on punishment and accountability after problems occur.

If the project is significant or the investment is high, it is more important to track the whole process, and the participants or arrangers should record the whole process, rather than being a shopkeeper,

You can also refer to APQP and PPAP related tools to control process quality.