How To Change The Raw Materials Of Two-color Injection Mold?

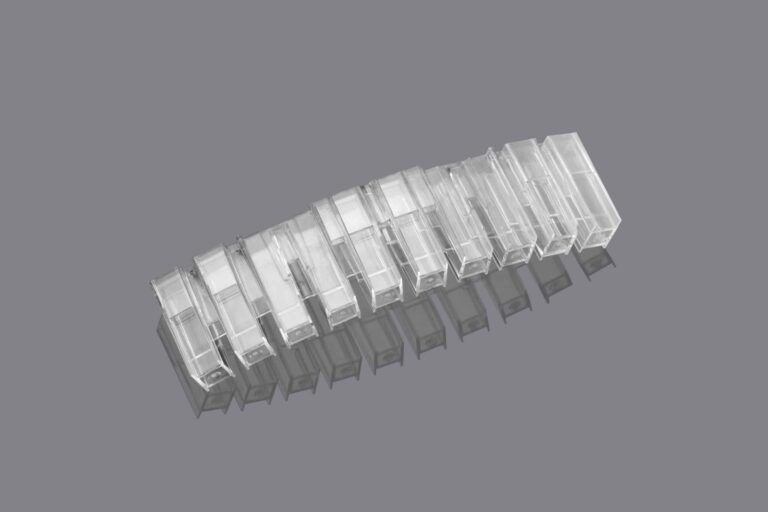

The two-color injection mold is also called double material injection molding, which is usually carried out by a set of stamping…

The two-color injection mold is also called double material injection molding, which is usually carried out by a set of stamping…

Many injection molding manufacturers will communicate with customers about the problem that the precision of injection molding thread does not meet…

Precautions for shutdown and restart during injection molding Plastic processing is the general term of various processes that convert synthetic resin…

The lathe is the master machine of all equipment, as is the case for plastic mold factories, so the understanding and…

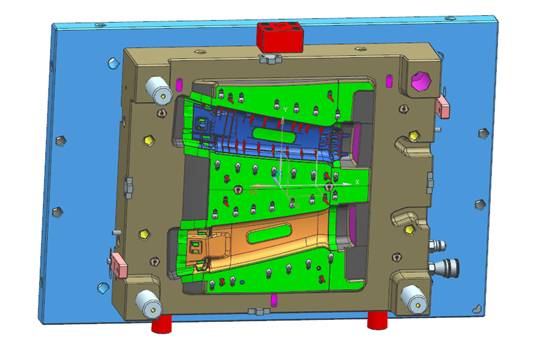

What should be paid attention to when selecting the mold surface in mold design? Mold parting surface Mold terminology. Generally…

Because the hot runner mold has high requirements for plastics, the hot runner must be selected according to the specific plastics…

Flap edge, also known as flash, overflow, overflow, etc., mostly occurs in the opening and closing position of the mold, such…

Since the 21st century, China’s automobile industry has achieved full development and rapid growth. It has become a leader in automobile…

Daily precautions for injection molding staff 1: In daily production, we will have environmentally friendly products, and the corresponding labels…

During injection molding, there will not be a lot of molten materials oozing from the vent hole, because the molten materials…

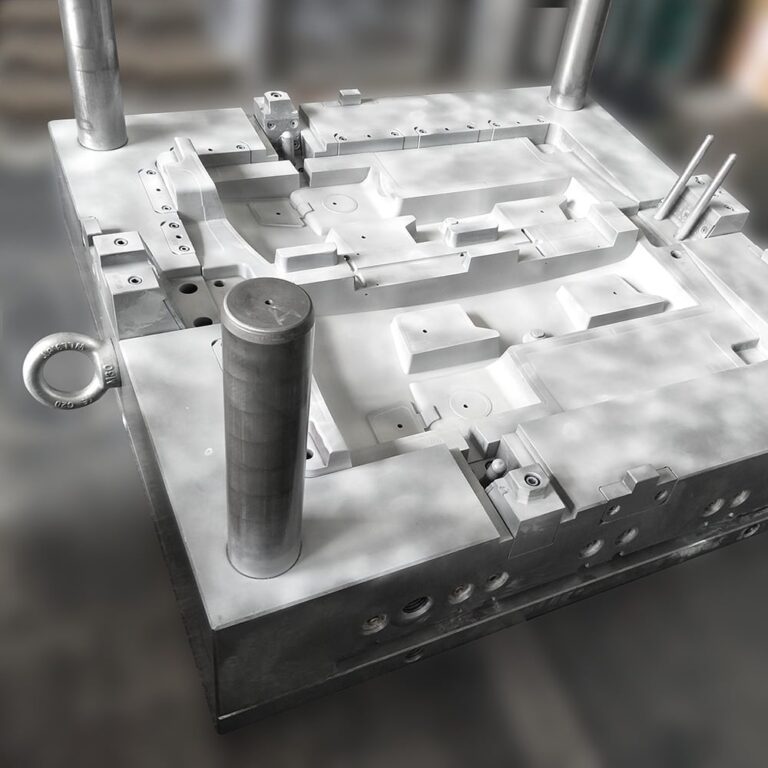

Injection Mold Maintenance Plan 1、 Inspection and maintenance during mold installation 1. Clean the upper and lower surfaces of the injection…

Attention shall be paid to whether there are scratches, missing parts, looseness, etc., whether the action of the die sliding plate is accurate, whether there is leakage in the water channel and gas pipe joints, and if there is a limit to the opening of the mold, it shall also be marked on the mold.

Reasons for gas generation during product manufacturing 1. The gas entrained by the material in the feeding system or the air…

Sharing of Process Specifications for Grinding and Polishing of Injection Mold Surface 1、 Preparation before grinding and polishing 1. The grinding…

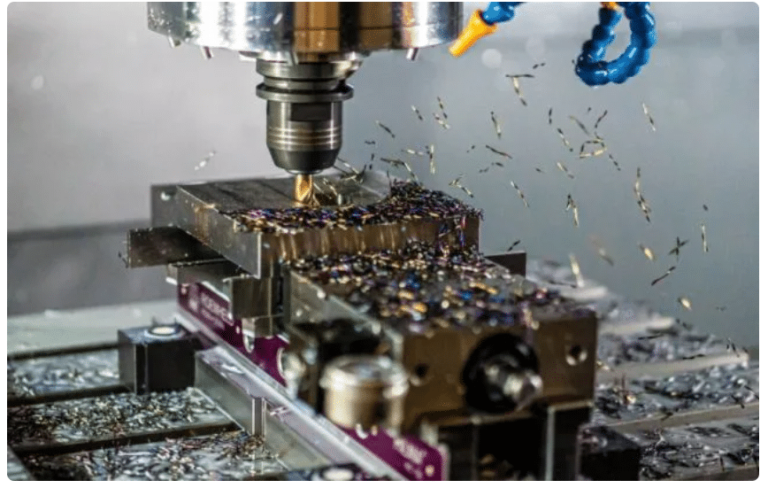

The role of cutting oil in die manufacturing Cutting oil plays an important role in the mold manufacturing process….

Contact us today for your custom solutions and experience precision, efficiency, and excellence!