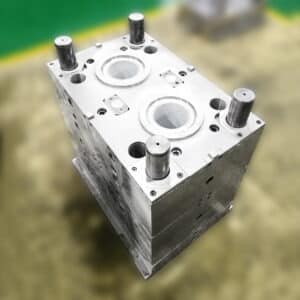

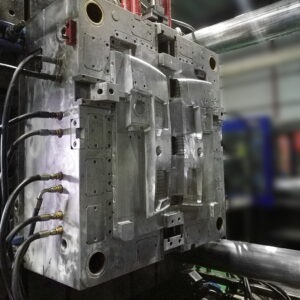

What Are The Characteristics Of The Appearance Design Of Injection Moulds?

What are the characteristics of the appearance design of injection moulds? Appearance design can leave a deep impression, consumers can’t see the internal quality of the product, but they can observe whether the product’s appearance design is smooth and the process quality is good, and then do a good job of overall accurate positioning of the product, such as appearance design is not standard, it may lead to the injection mold completely scrapped, so be