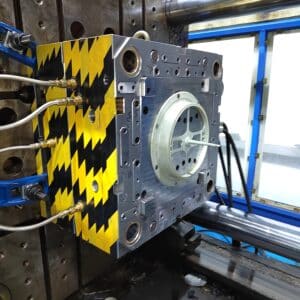

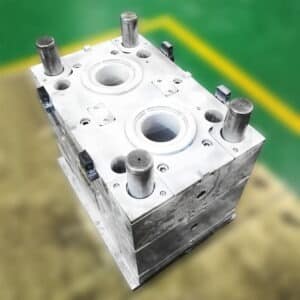

Application of New Hot Runner Flow Regulation System Technology

Application of New Hot Runner Flow Regulation System Technology 1、 Traditional problems: There are some problems in the traditional production mode of centrifugal fan blades, such as serious waste of runner materials, low product qualification rate and poor dynamic balance of products· The fine nozzle cold runner is adopted for glue feeding, which produces a lot of waste materials and wastes raw materials seriously· After pressure maintaining, one chamber is overweight, the product qualification rate