The Trend Of Cnc Machining Of Precision Instrument Parts In The Medical Industry

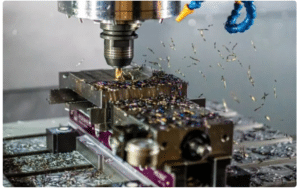

The trend of CNC machining of precision instrument parts in the medical industry With the continuous progress of society and technological innovation, precision CNC machine tools are increasingly used in the medical field. Medical device parts have the characteristics of complex structure, tough materials and difficult processing. The CNC processing of medical precision instrument parts is directly used for finished products, so the requirements for appearance are very high, and it must be achieved with