How to choose a suitable and powerful manufacturer from thousands of injection molding manufacturers?

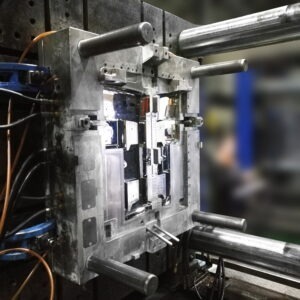

How to choose a suitable and powerful manufacturer from thousands of injection molding manufacturers? I think the following points should be paid attention to: Price is not unique. Quality, cycle and service are also important There are many types of injection molds. Generally, injection molding manufacturers will choose different processing technologies according to the material, physical and chemical properties, service life, dimensional accuracy requirements, and other factors. Due to the differences of the parts, more