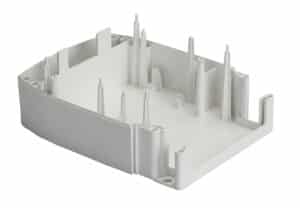

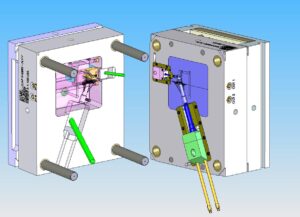

Principles of Plastic Injection Overmolding Technology

Secondary injection molding technology In the past 10 years, secondary injection molding technology has completely changed the aesthetic standards, design ideas and functional requirements of consumer goods. Medical device manufacturers also recognize the potential advantages of this technology and continue to expand its application in the medical field. The secondary injection molding technology is famous for creating a “soft surface”, but it also has many other functions, such as ergonomic design, two-color appearance, brand identity