How Can The Injection Mold Factory Effectively Reduce The Processing Cost?

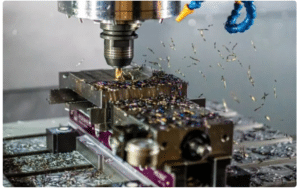

How can the injection mold factory effectively reduce the processing cost How should the injection mold factory effectively reduce the cost of injection mold processing? If it can effectively improve the economic benefits of enterprise production, can effectively reduce the cost of production, it will be conducive to the improvement of the competitiveness of enterprises and products in the market. First of all, injection moulds should be reasonably selected. Before the production of products, carefully