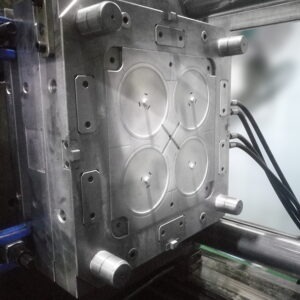

Two-Color Mold Working Principle

Two-color mold working principle A two-color mold is a mold in which two plastic materials are injected on the same injection molding machine and molded in two parts, but the product only comes out of the mold once. So how does the working principle of two-color mold injection processing work? The two-color mold usually has two sets of molds, half of which are mounted on the fixed plate of the two-color mold injection molding machine,