How To Control The Service Life Of Dies

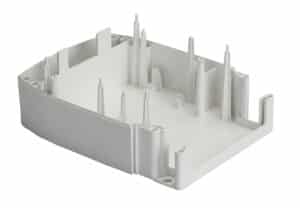

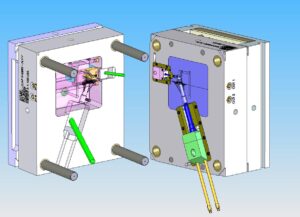

How to control the service life of dies Mold is closely related to our life. It can be said that modern people are increasingly inseparable from the use of mold products. For example, mobile phones, televisions, water cups for drinking… and the quality is so good that people doubt it. The mold time is that every time our mold is closed for production, it is called 1 mold time. How many times has a