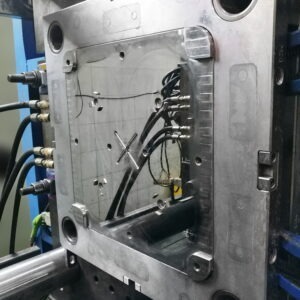

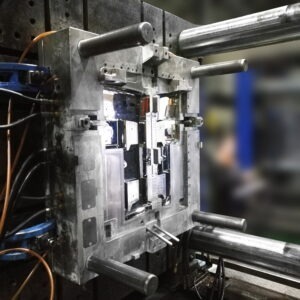

The Role Of Cutting Oil In Die Manufacturing

The role of cutting oil in die manufacturing Cutting oil plays an important role in the mold manufacturing process. The excellent refrigeration performance and extreme pressure wear resistance have made a qualitative leap for the service life of NC inserts and the improvement of mold shell manufacturing precision. According to the different workpiece materials, the performance of cutting oil is also different. It is generally determined according to the difficulty coefficient of die