Classification Of Mold Rust Inhibitor And Rust Prevention Oil

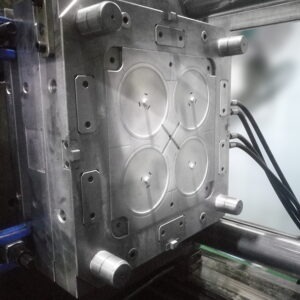

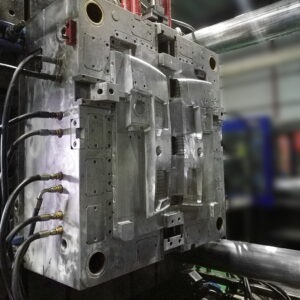

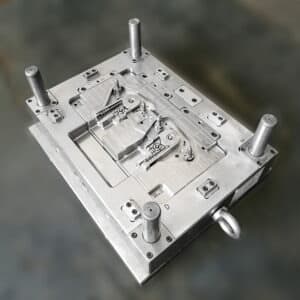

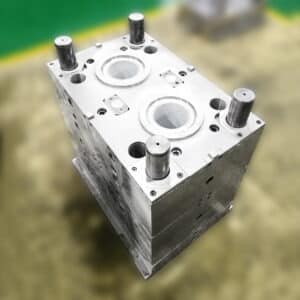

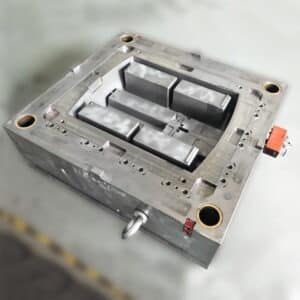

Classification of mold rust inhibitor and rust prevention oil Rust prevention for molds is essential. From the smallest to the cups of daily necessities, to the manufacturing industry such as automobiles and ships. There are many manufacturers who are prone to rust in air exposure and the service life of molds is greatly shortened because of choosing the wrong anti-rust products. The reason is that there are so many types of rust inhibitors and rust