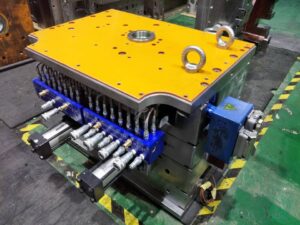

Differences between hot runner mold and cold runner mold

Differences between hot runner mold and cold runner mold The mold is a kind of molding equipment, with good molding effect and basically no deformation after molding. Now there are more and more types of molds. The main reason why the hot runner mold is widely used is its hot runner system. What is the difference between it and cold runner mold? In fact, the difference between the two is mainly in hot runner and