What Are The Principles And Core Of Injection Mold Design?

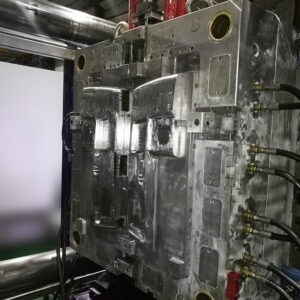

What Are The Principles And Core Of Injection Mold Design? Opening direction and parting line The opening direction and parting line of each injection molding product must be determined at the beginning of design to ensure that the core pulling slider mechanism is reduced as much as possible and the influence of parting line on the appearance is eliminated. 1. After the mold opening direction is determined, the stiffeners, buckles, bulges and other