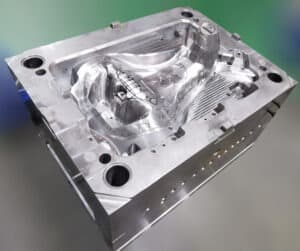

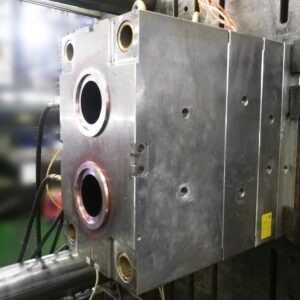

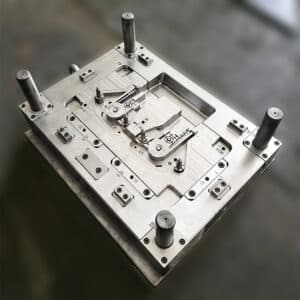

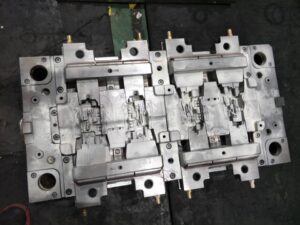

Rust causes of injection mould and solutions

Rust causes of injection mould and solutions: As we all know, injection molds are mainly made of tool steel. During work, they will encounter corrosive gases, water and other substances that cause rust. Plastic parts made of rusty molds often have quality problems, so we must find out the causes of rust in the molds and solve them. Reason 1: When the mold raw materials are overheated, they will produce volatile gases, which are mostly