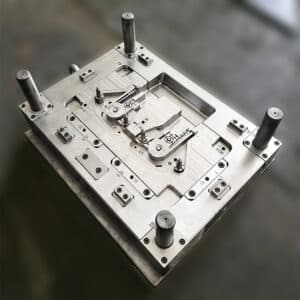

Analysis Of The Causes Of Shrinkage And Depression Of Injection Molded Products

Analysis of the causes of shrinkage and depression of injection molded products In the process of injection molding, shrinkage and depression of products is a relatively common phenomenon. The main reasons for this situation are. 1. Machine aspect. (1) the injection nozzle hole is too large to cause shrinkage due to reflux of molten material, too small resistance to the amount of material is not enough to appear shrinkage. (2) Insufficient clamping force will also