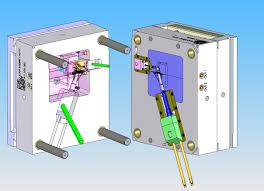

What Is The Main Flow Of Plastic Mold?

What Is The Main Flow Of Plastic Mold? The main runner refers to the section from the contact part of the injector nozzle and the mold to the branch runner. Design considerations: (1) The end face of the sprue is usually circular. (2) In order to facilitate demoulding, the main runner is generally made with a slope. However, if the main runner passes through multiple plates at the same time, pay attention to the slope